Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

1. Product principle of Corrosive liquid level sensor

Corrosive liquid level sensor suitable for strong acid, alkali, high temperature, high pressure, steam and other harsh conditions, the maximum measuring range of up to 30 meters.The radar level antenna emits narrow microwave pulses, which are transmitted downward through the antenna. After the microwave contacts the surface of the measured medium, it is reflected back and is received again by the antenna system. The signal is transmitted to the electronic circuit part and automatically converted into a level signal (because the microwave propagates extremely fast, the electromagnetic wave reaches the target and is reflected back to the receiver. The time taken is almost instantaneous).

2. Technical parameters of Corrosive liquid level sensor

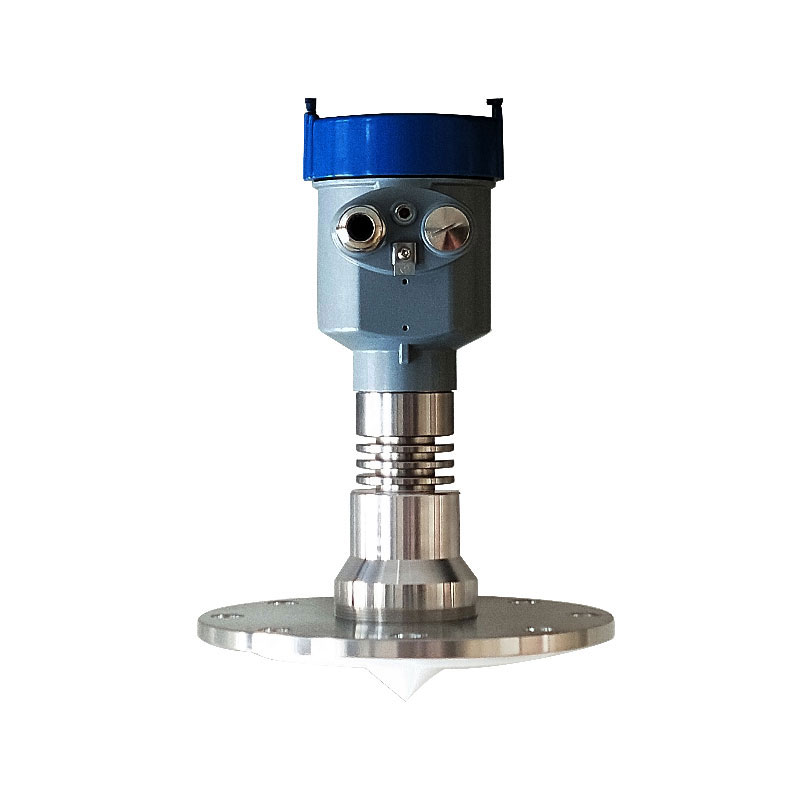

Product Features: PTFE cone antenna

Typical applications: liquids, powders, places with high hygiene levels, places prone to crystallization, condensation, and easy adhesion of oil fumes and dust, etc.

Measuring range: 30 meters

Antenna material: PTFE (optional)

Accuracy: ±5mm

Process temperature: -40~260℃

Process pressure: -0.1~4.0Mpa

Power supply: 24vDC (two wires, four wires)

Signal output: 4~20mA/Har (two wires/four wires)

RS485/Modbus

Process connection: flange (≥DN50 optional)

Protection level: IP67

Frequency range: 26GHz

Protection level: IP67

Explosion-proof level: ExiaⅡC T6 Ga/Exd ia IIC T6 Gb

On-site display: LED (standard configuration)

Cable entry: M20*1.5, ½NPT (optional)

Shell material: cast aluminum, 304 stainless steel (optional)

3. Corrosive liquid level sensor product features

The antenna is small in size and easy to install; the non-contact radar has no wear and pollution.

Almost unaffected by corrosion and foam; almost unaffected by water vapor, temperature and pressure changes in the atmosphere.

Serious dust environment has little impact on the operation of high-frequency level meters.

The wavelength is shorter and reflects better on tilted solid surfaces.

The beam angle is small and the energy is concentrated, which enhances the echo capability and helps avoid interference.

The measurement blind area is smaller, and good results can be achieved for small tank measurements.

High signal-to-noise ratio for better performance even under fluctuating conditions.

High frequency, it is the best choice for measuring solids and low dielectric constant media.