Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

Hidden cracks refer to tiny, barely visible micro-cracks inside solar cells. Similar to wormholes in wood or the crackle patterns within porcelain, the external surface of the module may appear intact while the internal structure is already damaged.

The harm caused by hidden cracks is not immediate but gradually manifests over time. Due to their concealed and delayed nature, they are often called "silent killers." They lead to power degradation: the cracks disrupt the internal current transmission path within the cell, preventing part or all of the current from being effectively outputted, resulting in permanent reduction of the module’s power generation capacity.

More dangerously, they can trigger the hot spot effect—the most hazardous consequence. Severe hidden cracks increase the resistance of certain parts of the cell, causing localized temperatures to rise sharply during operation (reaching up to several hundred degrees Celsius) and forming hot spots. Hot spots not only accelerate module aging but are also one of the primary causes of fires in photovoltaic power stations.

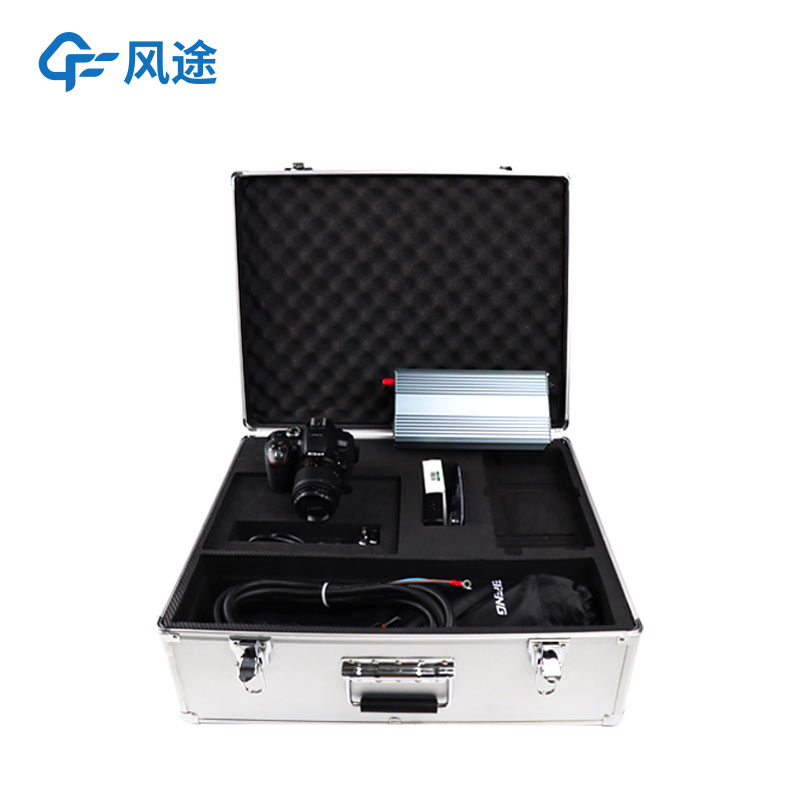

It is precisely for these reasons that there is a growing demand for a fast, accurate, and non-destructive detection technology. The Photovoltaic Panel Hidden Crack Rapid Detection Instrument (Portable EL Tester) is an important technical tool in the operation and maintenance of PV power stations. It can quickly and accurately identify internal damage in PV modules that is difficult to detect with the naked eye, such as hidden cracks, broken fingers, cell breakage, and PID degradation.

The principle is based on the electroluminescence (EL) effect. A forward bias voltage is applied to the PV module, causing it to emit light. Defective areas appear darker in the image due to obstructed current flow, forming dark spots or black lines.

Advantages:

Testing time for a single module can be reduced to a few seconds or up to 30 seconds.

The detection process causes no damage to the module.

The equipment is lightweight and portable, supporting use in complex on-site environments such as rooftops and mountainous areas.