Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

one. Water quality conductivity sensor application environment description

Water quality conductivity sensor can be widely used in the continuous monitoring of water quality, aquaculture, sewage treatment, environmental protection, pharmaceutical, food and tap water and other aqueous solutions.It is used for environmental water quality testing and testing of various high/low ionic strength water samples, and can meet the requirements of most industrial/environmental applications for online conductivity measurement.

Signal output: RS485 (MODBUS-RTU).

Internal signal isolation technology, strong interference resistance.

Good reproducibility, thermal stability, low drift, small size, fast response

Easy and simple installation, 3/4NPT pipe thread, convenient for submersible installation or installation in pipes and tanks

Stable performance and long service life

IP68 waterproof standard

24*1.2 18*1.5*2 28*2 2

two. Water quality conductivity sensor technical performance and specifications

1.Water quality conductivity sensor technical parameters

| Measurement principle | contact electrode method |

| Signal mode | RS485 (MODBUS-RTU) |

| Measuring range | 0~10000uS/cm |

| Measurement resolution | 1 |

| Measurement accuracy | ±1.5%; ±0.1°C |

| response time | About 30s (98% still liquid) |

| Shell material | ABS and 316L stainless steel |

| temperature compensation | Automatic temperature compensation (M1820Z) |

| Cable length | Standard 5 meters |

| Supply voltage | 12-24VDC (0.4W@12V) |

| Measurement environment | Temperature 0~50℃ (non-freezing), <0.2MPa |

| Waterproof level | IP68 |

| Installation method | Submersible installation, NPT3/4 thread |

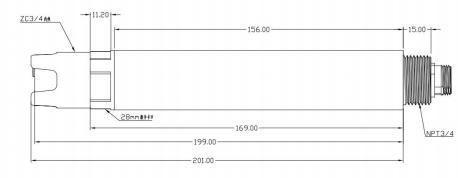

2.Water quality conductivity sensor dimension diagram

The sensor connector is M12 aviation plug connector 5-pin female seat

three. Water quality conductivity sensor installation and electrical connections

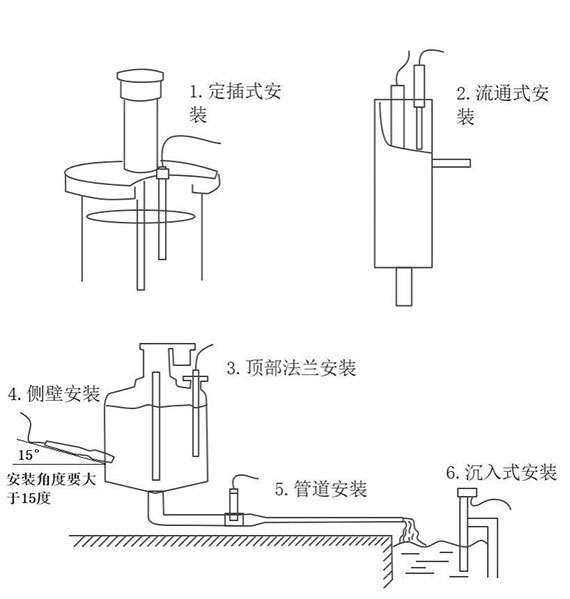

1.Water quality conductivity sensor installation

Note: The sensor cannot be installed upside down or horizontally, and must be installed at an angle of at least 15 degrees.

2.Water quality conductivity sensor electrical installation

The cable is a 5-core shielded wire, wire sequence definition: brown - power cord (12~24VDC)

Black - Ground (GND)

Blue-485A Green-485B

Yellow-4-20mA current output (can be left floating if not used)

The wiring sequence should be carefully checked before powering on to avoid unnecessary losses caused by wiring errors.

Four. Water quality conductivity sensor maintenance and care

1.Use and maintenance

Conventional electrodes require periodic cleaning and calibration, and the maintenance cycle is determined by the customer based on his or her own working conditions. Conventional electrode cleaning method: use a soft brush to remove attachments (be careful to avoid scratching the electrode surface), then clean with distilled water, and then perform calibration operations.