Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

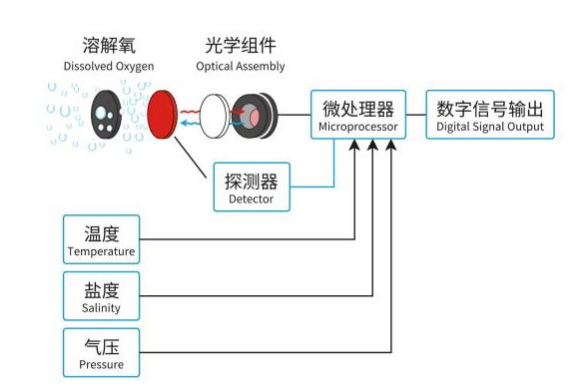

1.Working principle of Dissolved Oxygen Sensor

Dissolved Oxygen sensor The unique optical detection method of the probe can effectively measure molecular oxygen dissolved in water.The fluorescence dissolved oxygen sensor is designed based on the principle of quenching of excited fluorescence by specific substances in physics. When the excitation light shines on the fluorescent substance on the surface of the fluorescent membrane head, the fluorescent substance is excited and emits fluorescence. The extinguishing time of the fluorescence is affected by the concentration of oxygen molecules on the surface of the fluorescent membrane head. The concentration of oxygen molecules can be calculated by detecting the luminous lifetime of the fluorescence, and the final value can be output after temperature, air pressure and salinity compensation.

2. Dissolved oxygen sensor technical parameters

| Measuring principle | Fluorescence lifetime method |

| Measuring range | 0-20mg/L |

| Resolution | 0.01mg/L |

| Accuracy | ±2%, ±0.3℃ |

| Temperature compensation | Automatic temperature compensation |

| output method | RS-485 (Modbus/RTU), 4-20mA |

| storage temperature | -5~+65℃ |

| working environment | 0-50℃ , <0.3MPa |

| Installation | Immersion installation, 3/4NPT mounting thread |

| Cable length | 5m |

| Power consumption | 0.2W, 12V power supply |

| powered by | DC: 12V-24V |

| Protection level | IP68 |

| Calibration method | Two-point calibration |

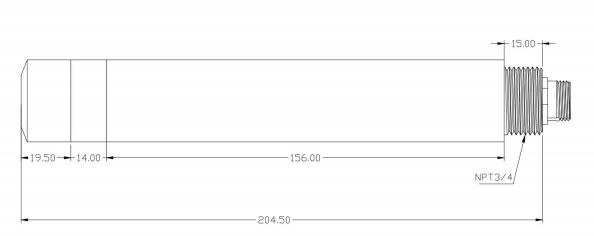

3. Dissolved oxygen sensor size/installation

1. Dissolved oxygen sensor dimensions

2. Dissolved oxygen sensor wiring diagram

The cable is a 4-core shielded cable:

Red line - power line

Blue wire—ground wire (GND) Green wire—485B

Yellow line—485A

The cable color may vary slightly due to different production batches. Please refer to the cable silk screen for details.

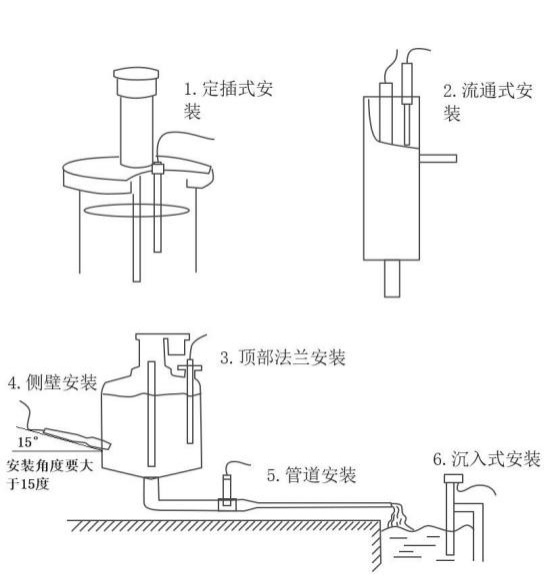

3.Dissolved oxygen sensor installation

Before powering on, the wiring sequence should be carefully checked to avoid unnecessary losses due to wiring errors, and the wiring points should be waterproofed.

4. Dissolved oxygen sensor maintenance and care

1) Sensor outer surface: Rinse the outer surface of the sensor with clean water. If there is still dirt remaining, wipe it with a damp soft cloth. For some stubborn dirt, you can add some household detergent to the water to clean it.

2) Surface of the fluorescent membrane head: If there is dirt on the surface of the fluorescent membrane head, please rinse it with clean water or wipe it gently with a soft cloth. Pay attention to the strength when cleaning to avoid scratching the measuring area and affecting the measurement accuracy.

3) If the measured value is too high or too low, the fluorescent membrane head needs to be cleaned and the membrane head needs to be stirred during measurement to prevent foreign objects from adhering to the membrane head surface.

5. Dissolved oxygen sensor calibration

5.1 Zero point calibration

Add 5g of sodium sulfite to 95mL of water and stir evenly. Place the sensor in the solution. After the value stabilizes for 3 minutes, perform zero calibration according to the communication instructions.

5.2 Slope Calibration

Place the sensor in air-saturated water, wait for about 3 minutes for the value to stabilize, then perform slope calibration, and perform zero calibration according to the communication instructions.

5.3 Notes

Avoid exposing the inner surface of the fluorescent film to sunlight or strong light. Do not touch the fluorescent film with your hands or sharp objects.

Avoid bubbles adhering to the surface of the fluorescent film during use