Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

1. Open Channel Flow Meter product overview

Open Channel Flow Meter can continuously monitor the flow of water in canals, and is suitable for flow measurement in various industrial and agricultural open channels.Open Channel Flow Meter (hereinafter referred to as the product) is a new generation Doppler flow meter developed by our company based on ultrasonic Doppler, spectrum analysis and low power consumption technology. The product consists of flow rate measurement module, liquid level measurement module, temperature measurement module, microcontroller, communication module, power supply module, etc. It integrates the measurement, storage and communication of flow rate, liquid level, temperature and flow rate. It is suitable for flow velocity and flow measurement in open channels, rivers, and drainage pipe networks, as well as flow velocity and flow measurement in various full and partially full pipes.

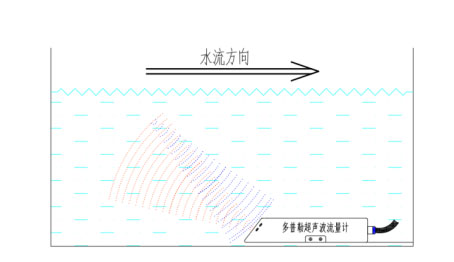

2. Working principle of Open Channel Flow Meter

Product flow rate measurement is based on the Doppler effect. The probe emits a beam of ultrasonic waves obliquely upward. When the ultrasonic waves contact impurities or bubbles in the fluid, the reflected ultrasonic waves will produce a Doppler frequency shift Δf. The Doppler frequency shift Δf is proportional to the fluid. Flow velocity, the flow velocity V of the fluid can be measured by measuring the Doppler frequency shift Δf.

The product measures liquid level based on a pressure sensor. It can automatically calculate the fluid cross-sectional area S through the set channel parameters. Based on the velocity area method, it can measure the flow rate Q of the liquid.

Q = V × S

Features

l Uses ultrasonic Doppler principle to measure flow velocity and measurement, with high accuracy and small environmental restrictions;

l The velocity area method is used to measure flow, without the need to build weirs and trenches, and the construction cost is low;

lHigh integration, supports simultaneous measurement of flow rate, liquid level, instantaneous flow, cumulative flow, and temperature;

l Comes with a temperature sensor to compensate for the impact of water temperature on the speed of sound;

l Built-in circular, rectangular, trapezoidal, triangular and other pipeline models for easy debugging;

lBionic appearance design effectively reduces garbage occlusion;

lLow power consumption design; operating current is less than 25mA; suitable for battery or solar power supply.

3. Open Channel Flow Meter parameter indicators

| Flow rate range | 0.02m/s~5m/s |

| Flow rate accuracy | ±1%FS |

| Flow velocity resolution | 0.001m/s |

| Liquid level range | 0~10m |

| Liquid level accuracy | ±0.5%FS |

| Level resolution | 0.001m |

| Flow range | 0.001~999999999m³/h |

| Flow accuracy | ±3% (varies according to cross-section shape) |

| Flow resolution | 0.001m³/h |

| Water temperature range | -20℃~60℃ |

| Water temperature accuracy | ±0.5℃ |

| water temperature resolution | 0.1℃ |

| Working voltage | DC 9~28V |

| Power consumption | <25mA |

| digital output | RS-485, Modbus RTU |

| size | 182*70*30mm |

| Material | ABS |

| Protection level | IP68 |

| Cable length | Standard 10m, can be customized according to needs |

4. How to use Open Channel Flow Meter

1. Installation requirements

Water quality requirements: According to the measurement principle, the water to be measured must contain certain tiny impurities or bubbles, but there should not be too many floating objects in the water to avoid interference.

Water flow pattern requirements: It should be installed downstream of a straight section with a fixed cross-section. The length of the straight section is preferably 5-10 times the hydraulic radius of the channel (the longer the straight section, the higher the measurement accuracy), and within this distance range There must be no overflow obstructions (such as sluices, weirs, etc.) to ensure a uniform and stable flow pattern in the front section of the probe.

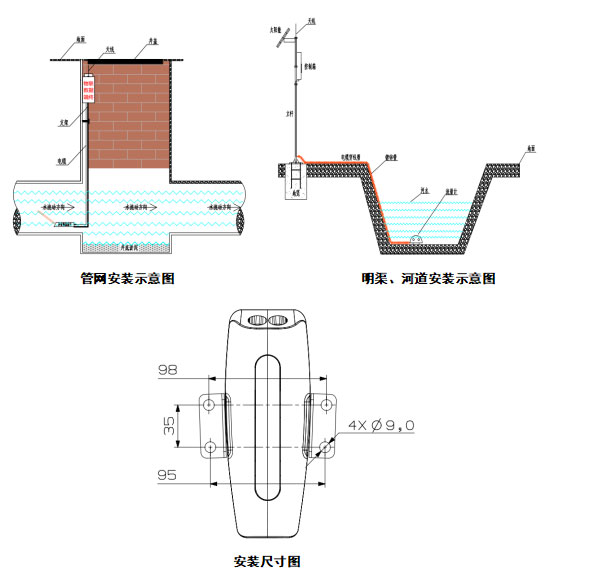

2. Installation diagram

3. Installation case

4. Daily maintenance

In order for the instrument to work properly, maintenance personnel are required to perform regular maintenance on the instrument.

l The two circular ultrasonic transceiver devices at the front of the sensor should be protected from impact or scratches by hard objects. When foreign objects are attached to them, they should be rinsed with clean water or lightly inspected with a soft cloth;

l The pressure sensor at the bottom is located in the mesh water permeable hole. Its pressure film is very thin and cannot be touched with hard objects. It should also be protected when the instrument is out of the water and not in use. Foreign matter attached around the water permeable hole should be carefully removed.

5. Questions and Answers

| Problem description | Check content |

| Communication error | Check whether the electrical connection is normal |

| Check whether the communication parameters and communication address are normal | |

| Flow velocity measurement value is abnormal | Check whether the ultrasonic probe is blocked by garbage |

| Check whether the liquid level passes the sensor | |

| Check whether the installation location is in a steady state of water flow | |

| Liquid level measurement value is abnormal | Check whether the liquid level passes the sensor |

| Check whether the liquid level probe is blocked | |

| Check whether the installation height is set properly | |

| Flow measurement value is abnormal | Check whether the channel parameters are set properly |