Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

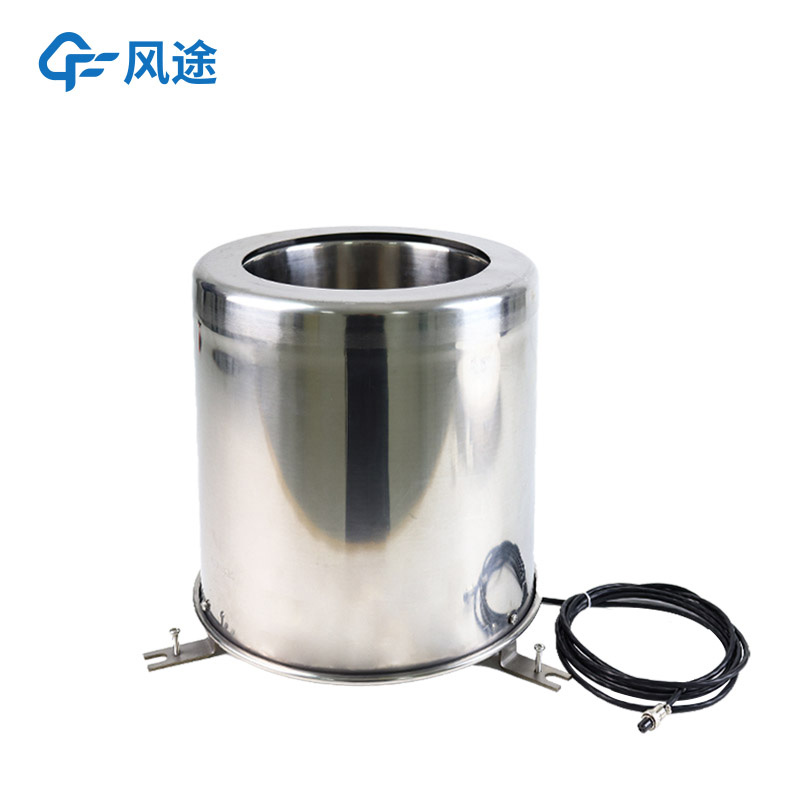

1.Working principle of evaporation sensor

The evaporation sensor is an instrument used to observe the evaporation of water surfaces. It has the advantages of high precision, high sensitivity, and wide range. It adopts a double-layer stainless steel structure design to prevent evaporation errors caused by direct sunlight. It has a higher accuracy than products in the same industry. Measurement accuracy value. Applying the pressure measurement principle, the evaporation amount is measured by measuring the weight change of the liquid in the evaporating dish and then calculating the height of the page. It can adapt to water surface evaporation measurement in various environments and is not affected by liquid freezing. It overcomes the shortcomings of using the ultrasonic principle to measure liquid level height, such as inaccurate measurement when freezing, easy damage to the sensor when there is no water, and low measurement accuracy.

2. Scope of application of evaporation sensor

The water surface evaporation sensor is a sensor used to sense changes in water surface evaporation. It can observe the changing patterns of water surface evaporation in different time periods. It is suitable for meteorological observation, plant cultivation, seed cultivation, agriculture and forestry, geological survey, scientific research and other fields.

It can be used with automatic water adding devices, data collection and sending devices, etc. to realize automatic monitoring of the evaporation process. It can also be used in combination with data collection and storage devices (recorders) to realize automatic storage of evaporation data. It can also be used with rainfall sensors and data collection devices. Used in conjunction with sending devices, etc., to achieve automatic observation and remote transmission of evaporation and rainfall processes.

3. Functional characteristics of evaporation sensor

1. It can prevent evaporation errors caused by direct sunlight, has higher measurement accuracy and faster response than products in the same industry;

2. The whole machine is made of 304 stainless steel, which is corrosion-resistant, rust-free, has a beautiful appearance and ensures the service life of the sensor;

3. Pressure measurement principle, using the high-precision weighing principle to measure the weight change of the liquid in the evaporation dish, calculate the liquid level height, and thereby measure the evaporation amount. The measurement is more accurate and the data is more scientific;

4. Double-layer protection design structure. This product adopts a double-layer stainless steel design, which can isolate external interference and make the measurement results more accurate;

5. When the power is turned on again after a power outage, the output data is still correct;

4. Working and storage conditions of evaporation sensor

Working temperature: -40~85°C

Working humidity: 0~100%RH

Storage humidity: <80% (no condensation)

5. Technical parameters of evaporation sensor

Supply voltage: 12V DC

Measuring range: 0~190mm

Measurement accuracy: ±1%

Signal output: 485 Modbus-RTU

Response time: 200ms

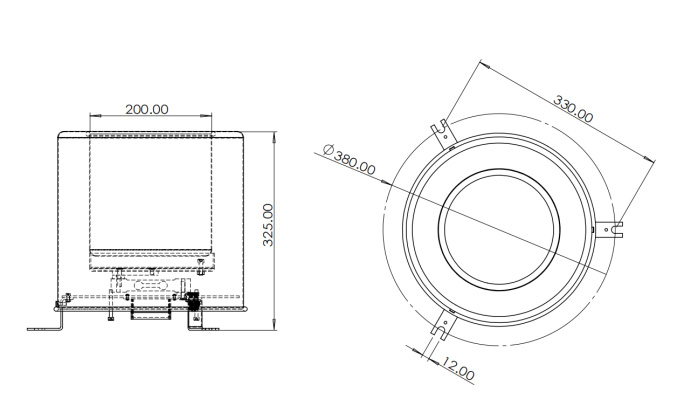

Inner barrel diameter: φ200mm

Protection level: IP66

6. Dimensional drawing of evaporation sensor product

7. Installation guidance of evaporation sensor

1.Instructions for selecting installation location

The installation location of the equipment should be higher than the ground and must be installed on a cement base to prevent rainwater from flooding the chassis and pouring into the equipment, causing equipment short circuit or line failure.

2. Installation steps

Unbox the product, place the outer shell, inner tank, and base on the level ground to prepare for installation. The installation steps are as follows:

ARemove the bottom top wire

BPlace the inner container on the base tray

C Cover the shell on the base chassis

D Rotate the housing so that the bolt holes at the bottom of the housing are aligned with the bolt holes on the base tray, insert the bolts and tighten them

E Fix the assembled equipment on the pre-made cement base