Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

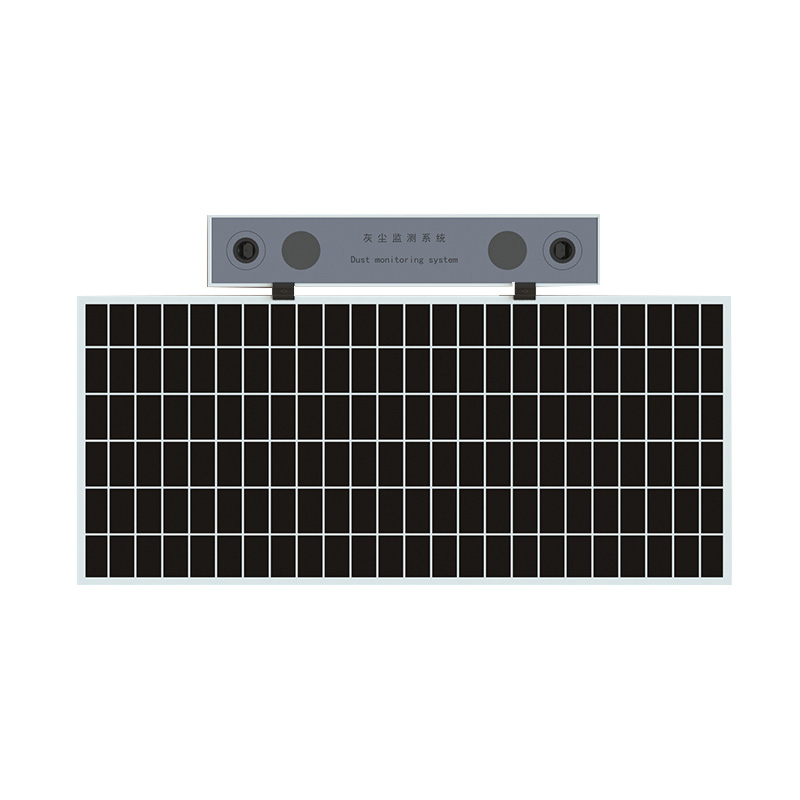

Photovoltaic module dust device, installed on the photovoltaic panel frame, uses blue light pollutant closed-loop measurement technology to monitor the area, thickness, and distribution of dust accumulation in real time. This effectively reduces the frequency of manual wiping, lowers maintenance costs, and improves power plant efficiency.

Dust accumulation on the surface of photovoltaic modules is a common factor affecting power plant efficiency. Dust blocks solar radiation, reducing photoelectric conversion efficiency, and uneven dust accumulation can lead to hot spot effects, accelerating module aging. Traditional cleaning relies on manual inspections and periodic wiping, which is not only costly but also makes it difficult to accurately determine when to clean. The Photovoltaic module dust device, designed specifically for photovoltaic modules, provides quantitative data for operation and maintenance by collecting dust coverage data in real time.

This device is installed directly on the photovoltaic panel frame without altering the module structure. It employs blue light pollutant closed-loop measurement technology, emitting stable blue light to the module surface and receiving the reflected signal to calculate the dust coverage area, thickness, and distribution characteristics in a closed loop. Optical measurement avoids ambient light interference, resulting in stable and highly repeatable data. Monitoring results are output in numerical or visual form, allowing maintenance personnel to view the dust accumulation status of each module through the platform.

Real-time monitoring data supports on-demand cleaning strategies. When dust accumulation reaches a set threshold, the system indicates the specific location and degree of contamination, allowing maintenance personnel to perform targeted cleaning and avoiding indiscriminate full-site cleaning. Compared to traditional periodic maintenance, this reduces wiping frequency by 30% to 50%, decreasing water consumption and labor costs while preventing excessive cleaning and abrasion of component surfaces. For large ground-mounted power plants or rooftop distributed projects, reduced manual inspection frequency also lowers safety risks associated with working at heights.

Dust distribution data can also be used to assess the impact of component tilt angle and installation environment on dust accumulation rates. Power plant operators can optimize cleaning cycles based on long-term monitoring results or adjust installation parameters during the design phase by referencing similar environmental data. The equipment itself has a protective structure, adapting to outdoor high-temperature, high-humidity, and sandstorm environments, resulting in low maintenance requirements.

The application of Photovoltaic module dust has expanded from large-scale centralized power plants to industrial and commercial distributed projects. The return on investment period is affected by the power plant size and local dust accumulation rate, typically recovering equipment costs within one to three years. In areas with higher electricity prices or generous subsidies, the increased revenue from increased power generation is even more significant. This equipment does not alter the electrical parameters of the photovoltaic modules, does not generate shadows, and does not consume power generation during operation. Its power supply is drawn from the modules themselves or from an independent power source.

With the continuous growth of photovoltaic installations, refined operation and maintenance have become crucial for improving power plant profitability. Dust detectors use data-driven methods to transform the impact of dust accumulation from qualitative assessment to quantitative management, providing actionable cleaning guidelines for power plants. The optical measurement technology it employs has proven stable under various climatic conditions. In the future, with the development of the Internet of Things and edge computing, equipment data can be directly integrated into the power plant monitoring system, enabling automatic early warning and联动 (linkage/coordination) with cleaning equipment. With the goal of reducing the cost per kilowatt-hour, dust monitoring is gradually becoming a standardized configuration for photovoltaic power plants.