Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

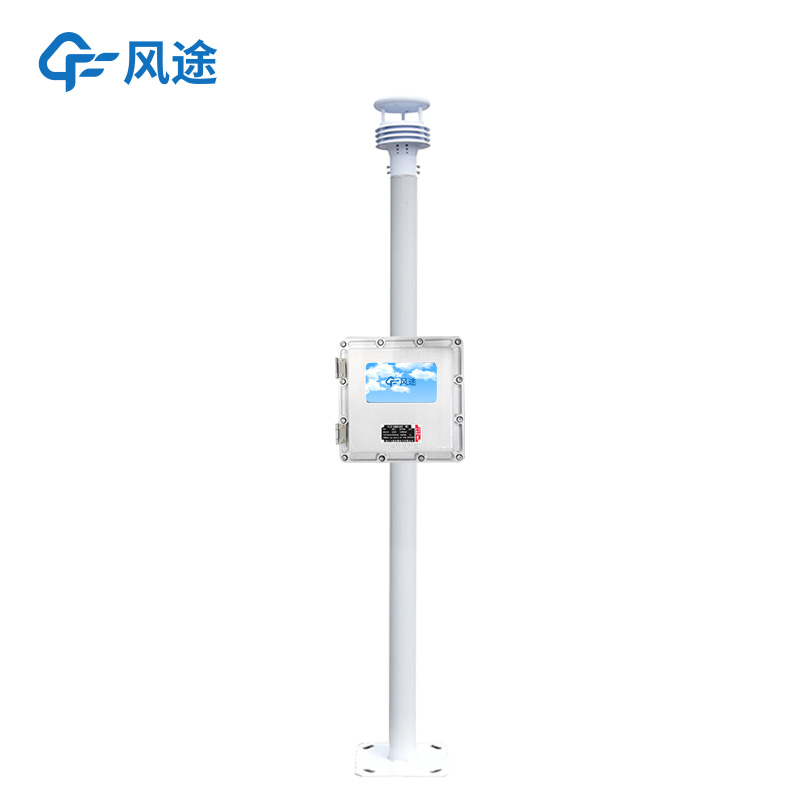

An Explosion proof weather station is a specialized meteorological monitoring device designed for hazardous environments with flammable and explosive gases, such as petroleum, chemical, and mining industries. It features explosion-proof design and multi-parameter simultaneous monitoring capabilities.

The equipment incorporates special designs from the outer casing to internal circuits to prevent electrical sparks or high temperatures from causing explosions. The outer casing is made of anti-corrosive and explosion-proof materials such as ASA engineering plastic or stainless steel. The interior achieves electrical isolation through intrinsically safe circuits (such as current-limiting and voltage-limiting technologies). The device has obtained certification according to national explosion-proof standards such as GB3836.1-2010 and GB3836.4-2010, with an explosion-proof rating up to Ex ia IIC T6 Gb, indicating its safe application in high-risk gas environments including hydrogen and acetylene.

Highly integrated with multiple sensors, it can simultaneously measure the following core meteorological parameters within a single explosion-proof housing:

Wind Speed: Ultrasonic measurement principle, 0~60m/s (±0.1m/s+0.01V), resolution 0.01m/s

Wind Direction: Ultrasonic measurement principle, 0~360° (±2°), resolution 1°

Air Temperature: Diode junction voltage method, -40-80℃ (±0.3℃ at 25℃), resolution 0.01℃

Air Humidity: Capacitive measurement principle, 0-100%RH (±3%RH between 20%~80%), resolution 0.01%RH

Atmospheric Pressure: Piezoresistive measurement principle, 300-1100Hpa (±0.25%), resolution 0.1hpa

The device supports RS232 wired transmission and has a built-in large-capacity memory (storing no less than 500,000 data points). It adopts standard protocols such as Modbus-RTU and can be integrated into factory DCS or PLC systems.

Applications:

Installed in oil depot tank farms and chemical plant production areas to monitor wind speed and direction in real-time, providing data support for optimizing ventilation systems and warning of dangerous gas diffusion

Mounted at mine entrances or inside tunnels to monitor light wind conditions and prevent accumulation of harmful gases such as methane

Used at natural gas processing stations and storage and transportation facilities to monitor meteorological conditions and assist in managing leakage risks

Also suitable for various other environments requiring explosion-proof monitoring