Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

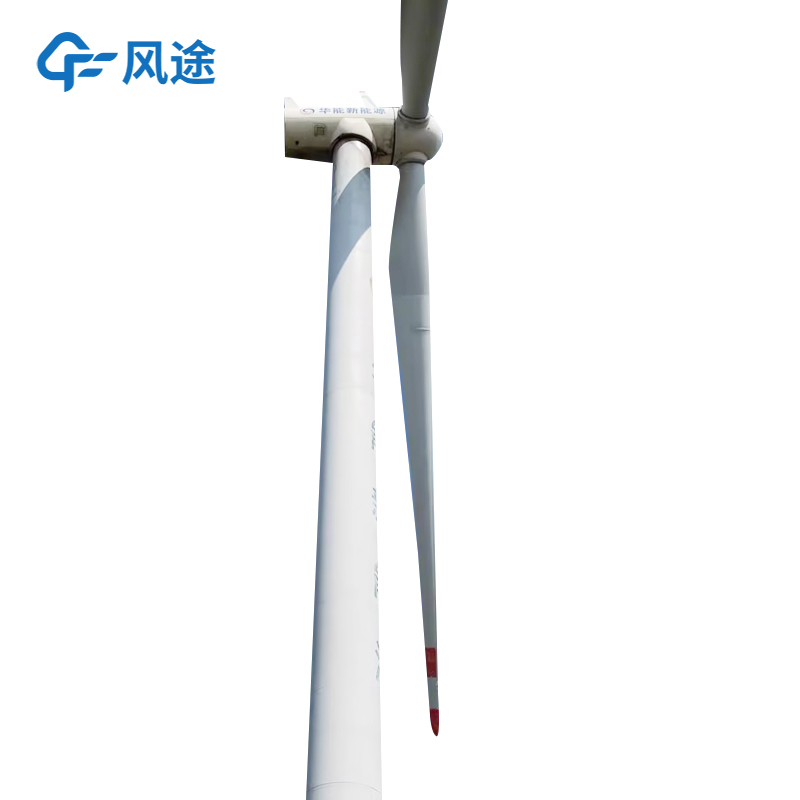

When the temperature approaches 0°C and the humidity is high, the blades of wind turbines are extremely prone to icing. After icing, the ice blocks may fall off due to gravity and the mechanical force generated by the rotation of the wind turbine, and be projected hundreds of meters away, posing a potential safety hazard to buildings, vehicles, and people. If the icing factor is not considered in the assessment of wind resources, the assessment results will be inaccurate.

Icing can change the aerodynamic profile of the blades, increase additional loads, cause extra vibrations, and shorten the service life of the wind turbines. In extreme cases, it may even lead to the collapse or damage of the wind tower. At the same time, foreign studies have shown that when the blades operate with ice, the power generation will decrease by 10% to 20%, resulting in an increase in the operation and maintenance costs of the wind farm, which has become a key factor restricting the development and construction of the wind power market in areas prone to icing.

However, it is difficult to accurately quantify the impact of icing on wind turbine blades because there are differences in the climatic and geographical conditions of different regions as well as the actual situations of wind farms. After the wind farm is built and put into operation, once the blades are iced, the impact on power generation efficiency, equipment life, and operation safety will vary depending on the region and conditions.

Detecting Ice on Wind-turbine Blades adopts microwave detection technology. Through the feedback characteristics of microwave signals to different substances such as ice, water, and air, it can monitor the icing information in the sensitive area of the sensor, and calculate the icing thickness according to the strength of the signals and the icing distribution. This sensor is usually installed on the blades of wind turbine generators. By monitoring the icing condition on the sensor in real time, it can effectively infer the icing situation on the surface of the blades.

This kind of sensor is widely used in cold areas at high altitudes and high latitudes as well as offshore wind farms. It can help operation and maintenance personnel take de-icing measures in a timely manner, reduce the downtime, and improve the power generation efficiency.