Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

Freezing has a negative impact on the operation of wind turbines, resulting in the degradation of key component performance and an increase in safety risks. As core sensors, anemometers and wind vanes are equipped with heating devices to cope with low - temperature environments. However, the heating range is usually limited to rotating parts. In severe freezing conditions, other parts of the sensors still ice up, leading to an increase in rotational inertia, a decline in measurement accuracy, affecting the judgment of the unit control system, and causing a decrease in power output or even shutdown.

Ice accretion on blades is another major problem. It not only increases the blade load but also causes unbalanced forces on the unit due to uneven ice accretion. This unbalanced load accelerates the fatigue of the unit and seriously affects its service life. Moreover, ice accretion changes the original airfoil structure of the blades, resulting in a decline in aerodynamic performance. The lift - to - drag ratio can be reduced by up to 61%, and the blades enter the stall zone earlier, greatly reducing the operating efficiency of the unit.

As the temperature rises, the ice on the blade surface may suddenly fall off, posing a serious safety threat to the unit equipment and on - site personnel. These factors jointly lead to a significant decrease in the availability and economic benefits of wind turbines in low - temperature regions. In other words, the industry needs anti - icing and de - icing measures.

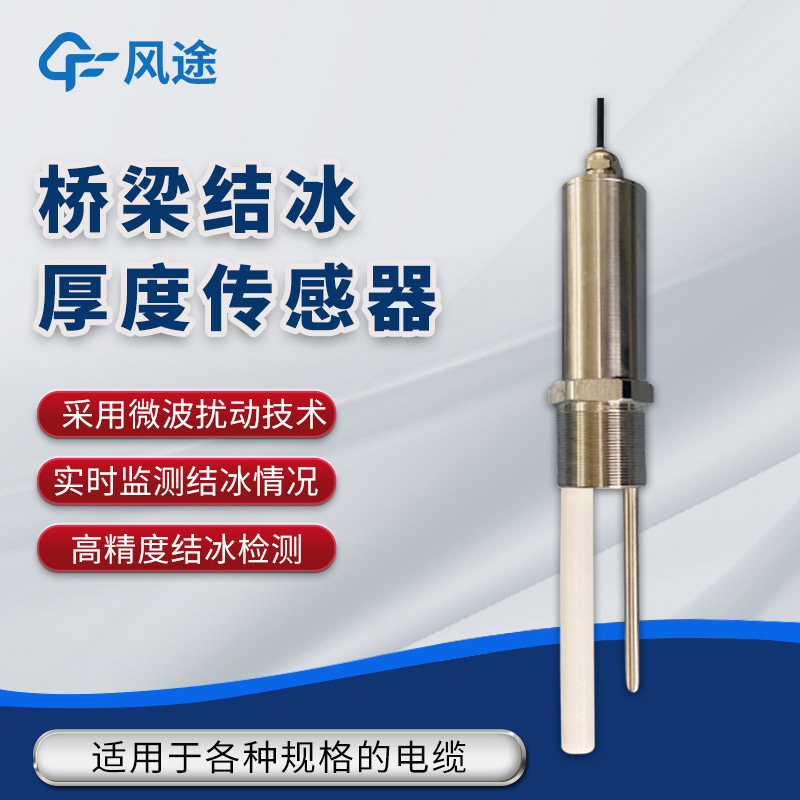

The Detecting Ice on Wind - turbine Blades FT - JB1H is an icing monitoring device specifically designed for power transmission lines. It is mainly used to detect the ice accretion on wires in real - time under low - temperature, rainy, and snowy weather conditions, preventing safety accidents such as pole collapse and wire breakage caused by ice accretion. This sensor adopts microwave detection technology. By analyzing the differences in the feedback of microwave signals to substances such as ice, water, and air, it realizes the monitoring of icing information in sensitive areas and calculates the ice thickness with an accuracy of up to 0.01mm and a maximum measurement thickness of 50.00mm.

It can not only detect the ice thickness but also identify weather conditions such as rain. It has a built - in temperature sensor to provide ambient temperature data. Its communication method is RS485, which supports the Modbus RTU protocol. It can actively send data at regular intervals or support the master - slave mode, making it suitable for large - scale monitoring systems.

The sensor is equipped with a de - icing device. When the power transmission line is de - icing, the de - icing function of the sensor can be started synchronously (requiring a separate power supply of 12VDC, 12W) to effectively deal with severe ice accretion situations.

It is installed on power line towers and is powered by a solar power supply system to support long - term operation in remote areas. It is also equipped with a 2G mobile communication module to achieve remote data transmission. Its unique device number design facilitates large - scale deployment and management, providing an important guarantee for the safe operation of the power grid.