Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

In regions with humid climates during winter and spring, icing on wind turbine blades is an unavoidable issue, often posing great challenges to the stable operation of wind turbines.

Generally, when the ambient temperature is below 0 °C, the blade surface temperature drops below -5 °C, and the air humidity exceeds 85%, the risk of blade icing increases significantly. Wind farms are often located at the intersection of frequent cold and hot airflows. The complex combination of micro-topography and micro-meteorology makes blade icing a common phenomenon for many units. Fundamentally, the icing on the blade surface results from the phase transformation of water at low temperatures. Supercooled water droplets that remain liquid below 0 °C are unstable. Once they strike the windward side of the blade leading edge, they quickly freeze into ice under the effect of coupled phase change.

There are mainly three types of icing. Glaze ice usually appears in environments with temperatures between 0 °C and 5 °C and high humidity. At this time, the supercooled water droplets are relatively large. After colliding with the blade, they first spread into a water film and then condense into transparent, hard, dense, and strongly adhesive icicles. Rime ice forms when the temperature is below -5 °C and the air water content is low. Small droplets form loosely textured, low-density, weakly adhesive icicles through dry growth. Mixed rime often occurs in mountainous areas with temperatures between -10 °C and -3 °C. High wind speeds carry clouds and fog, and water droplets of different sizes grow both wet and dry, creating semi-transparent, medium-density, firmly attached ice bodies on the blade windward side.

When it comes to the impact on the unit, power output is the first to be affected. The windward side of the blade and the blade root are the hardest-hit areas for icing. Slight icing can make the blade surface rough, reducing its aerodynamic performance and thus the power; in severe cases, the torque drops to zero, the output power disappears completely, and the unit may even be forced to shut down.

Take the Vestas V80 - 1.8MW wind turbine as an example. The glaze ice accumulation can reach 709 kg, accounting for 11% of the blade weight, causing the tip resistance to soar by 365% and the lift force to plummet by 40%. The rime ice accumulation is 434 kg, accounting for 6.7% of the blade weight, with the tip resistance increasing by 250% and the lift force decreasing by 40%. Moreover, icing can also lead to imbalance of static and dynamic loads of the unit, severe vibration, blade frequency fluctuation, increased fatigue loads and bending moments. What's more, it can even pose a threat to the personal safety of operators. Facing the problem of wind turbine blade icing, only by thoroughly exploring the causes and taking comprehensive measures can we ensure the safe and efficient operation of wind farms.

Given the current state of technology, it is impossible to completely eradicate the icing problem. We can only take measures to de-ice after icing occurs to reduce economic losses.

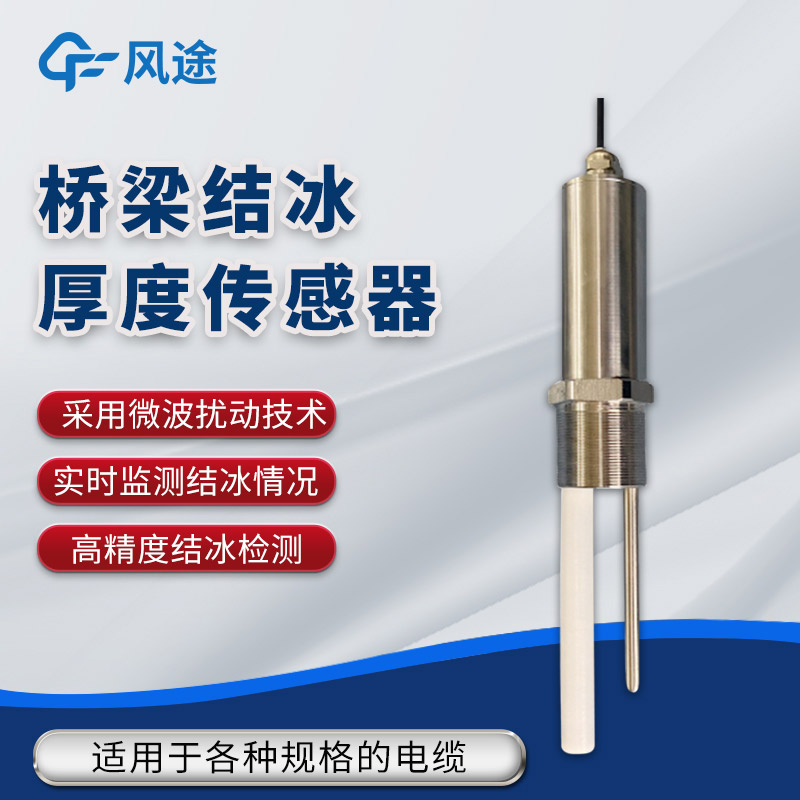

This requires doing a good job in icing monitoring during the high-incidence season. The Detecting Ice on Wind-turbine Blades FT-JB3H can be used.

This is a professional sensor used to monitor ice accumulation. It is installed on the blades of wind power generating units. Its principle is based on microwave detection technology. By utilizing the differences in feedback information of microwave signals for different substances such as ice, water, and air, it monitors the icing information in the sensitive area of the sensor and can calculate the icing thickness according to the signal strength and icing distribution information.

The sensor has a temperature detection and compensation function, a simple structure, and convenient installation. It is equipped with an RS485 communication interface and can communicate using the Modbus RTU protocol. It can also be set to send data at fixed times to meet various communication needs.