Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

In the photovoltaic industry, the quality of solar cells has a decisive impact on the performance and stability of the entire photovoltaic system, and microcracks are a problem that cannot be ignored. Microcracks refer to the tiny cracks that exist inside the solar cell, and these cracks are usually difficult to be directly observed by the naked eye in appearance. However, their hazards should not be underestimated. Microcracks will increase the series resistance of the cell, leading to a decrease in current generation capacity, thereby reducing the conversion efficiency of the cell. Moreover, with the passage of time and the influence of environmental factors, microcracks may further deteriorate and eventually cause the cell to fail.

The EL detector works based on the photoelectric characteristics of crystalline silicon. When a forward bias voltage is applied to the solar cell, the cell will emit infrared light. The high-sensitivity camera of the EL detector can capture this infrared light and convert it into an image signal, thus clearly showing the actual situation inside the cell. In the EL image, the normal area of the cell will show a relatively uniform luminous state. In the area with microcracks, since the microcracks damage the crystal structure and electrical properties inside the cell, the carrier recombination rate in this area is greatly increased, so the luminous intensity is significantly weakened, and it will appear as a clear dark line in the image, so that the location of the microcracks can be accurately identified.

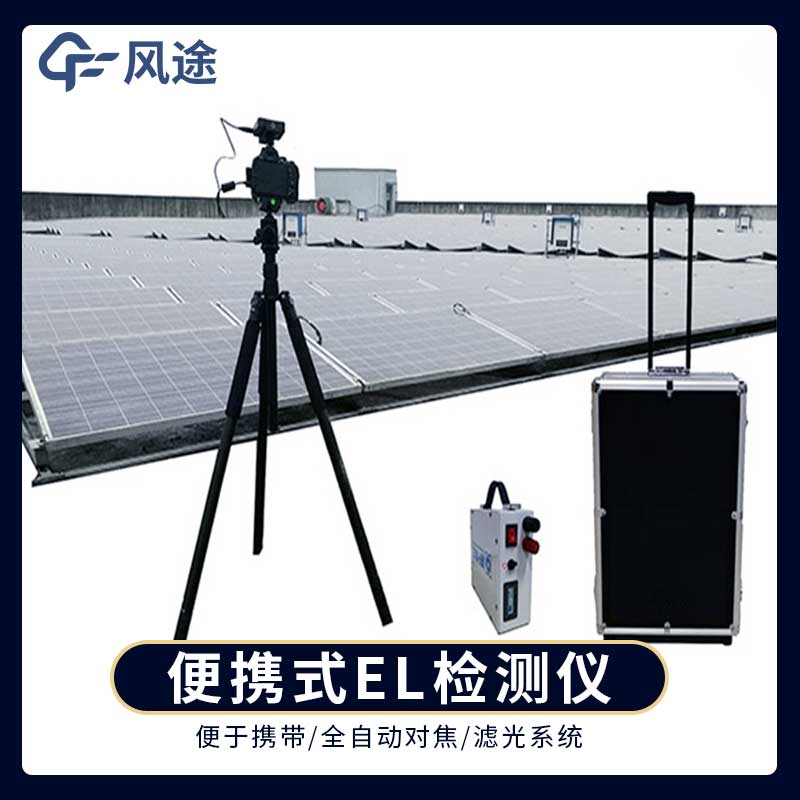

Using the EL detector in the production process can timely screen out the cells with microcracks, ensure product quality, and prevent defective modules from entering the market circulation. In the operation and maintenance of photovoltaic power plants, EL detection is also extremely critical. By regularly using the EL detector to detect the modules, potential faults such as microcracks can be quickly and accurately detected, so that maintenance measures such as replacing the defective cells or modules can be taken in a timely manner, effectively improving the power generation efficiency of the photovoltaic power plant and ensuring its reliable operation.