Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

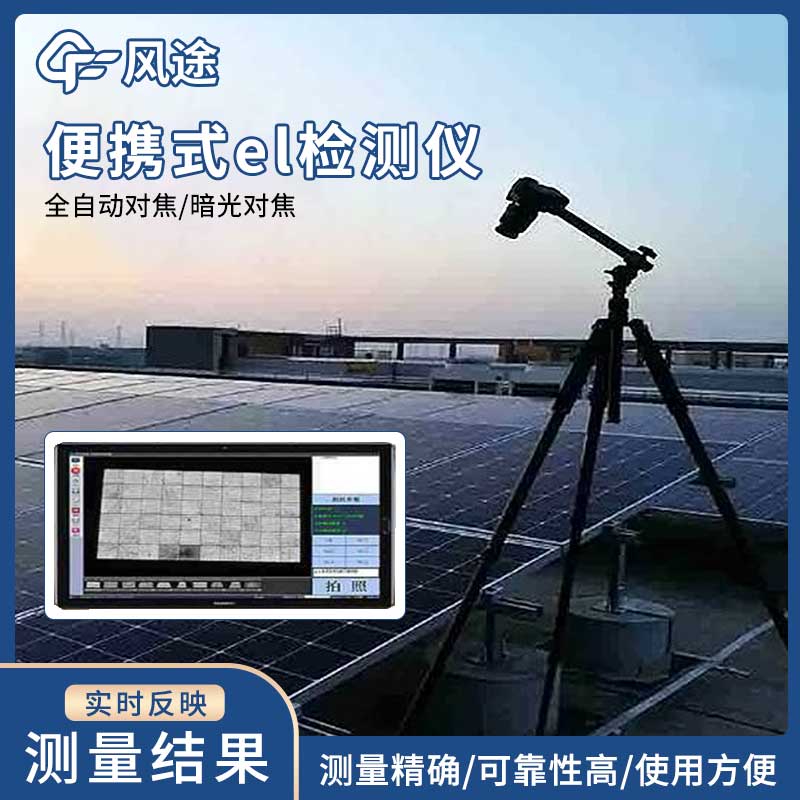

Electroluminescence is a method of testing the quality of a solar cell. By energising the solar cell, it emits light. We then capture this light with a special imaging system and process it through computer software to finally display an EL image of the solar cell on the screen.

This image helps us to check if there are any problems with the solar cell, such as hidden cracks or damaged parts, because its brightness is related to the current density.

Photovoltaic modules are made of materials such as photovoltaic glass, cells and backsheets bonded together by an adhesive film and reinforced all around with an aluminium frame to provide extra strength. The cells are susceptible to hidden cracks or splinters from external forces such as stepping, impact or vibration. These damages can reduce the power generation efficiency of the PV module and may pose a safety hazard.

PV modules need to pass electroluminescence (EL) testing to ensure their quality before they leave the factory. However, there are two aspects of the transport of the modules to the project site and connection to the grid that are particularly susceptible to hidden cracks:

During transport, if the packaging is not secure enough or the road is bumpy, hidden cracks may occur in the cells inside the module.

During installation, hidden cracks in the cells may also be caused if workers handle the modules improperly or roughly.

For PV modules, to make sure they are not damaged, the manufacturer performs two special light tests, called EL tests, upon receipt and after installation. This test is done by specialised personnel who randomly select a number of modules for inspection. If the number of problematic components found is within acceptable limits, then the batch is considered to be satisfactory. If problems or extreme weather are encountered during operation, the plant will also perform the EL test again to ensure the performance of the modules.

Internal problems with PV modules that can be detected using an EL monitor include:

Hidden cracks: dark areas in the form of diagonal lines, usually starting at cell edges or grid lines.

Grid breaks: black broken bands at thin grid lines.

Void soldering: areas near the main grid lines appear brighter in the EL image.

PID: Large dark spots appear in the image.

Cell mixing: The electrical properties of different cells result in different light and dark in the image.

Diode short circuit: Some cells are not bright at all in the image.

Fragmentation: Cells have black sharp or irregular broken areas with poor appearance.