Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

Introduction to ultra-low CEMS smoke monitoring system

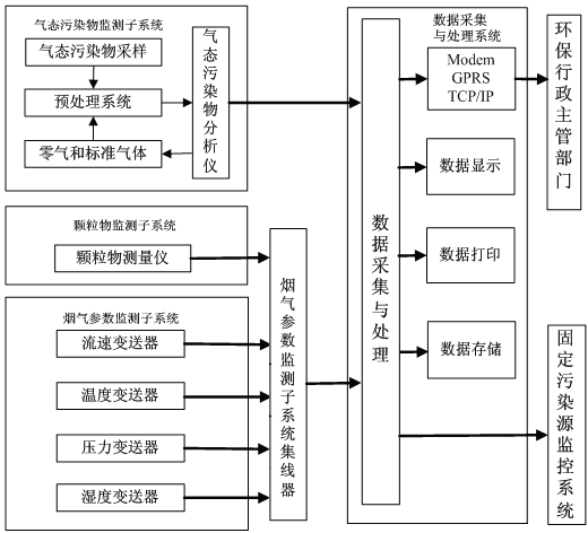

Ultra-low CEMS flue gas monitoring system is also called CEMS ultra-low emission flue gas online monitoring system and ultra-low flue gas continuous detection system. The ultra-low CEMS flue gas monitoring system consists of gaseous pollutant monitoring, particulate matter monitoring, flue gas parameter monitoring and data It consists of four required subsystems for collection and processing.

The flue gas emission continuous monitoring system launched by Fengtu Technology can continuously monitor SO2, NOX, 02 (standard, wet basis, dry basis and converted), particulate matter concentration, flue gas temperature, pressure, flow rate and other related parameters, and collect statistics Emission rate, total emissions, etc. Thus the measured data can be effectively managed.

The system consists of four required subsystems: gaseous pollutant (SO2, NOX, 02, etc.) monitoring, particulate matter monitoring, flue gas parameter (temperature, pressure, flow rate, etc.) monitoring and data acquisition and processing.

Gaseous pollutant monitoring uses extraction condensation method + phosphoric acid titration method for pretreatment. The principle is to use the ultraviolet differential method to measure the SO2 and NOX content in the flue gas, measure the wet oxygen content through the electrochemical method, and then calculate the SO2 through dry-wet conversion. , NOX, 02 dry flue gas concentration, phosphoric acid titration hair pretreatment can effectively reduce the adsorption loss of SO2 during condensation and water removal, and improve measurement accuracy.

Particulate matter monitoring adopts the extraction measurement method, the temperature of the flue gas is measured by a temperature sensor, the flue gas pressure is measured by a pressure sensor, and the flue gas flow rate is measured by a pitot tube; all measurement signals are sent to the data acquisition and processing system.

The output processing system has functions such as real-time transmission of on-site data, remote fault diagnosis, report statistics, and graphic data analysis, enabling unattended work sites. The entire system has a simple structure, wide dynamic range, strong real-time performance, flexible networking, and low operating costs. At the same time, the system adopts a modular structure and is easy to assemble. It can fully meet the requirements for communication with the internal DCS system of the enterprise and the data system of the environmental protection department. .

000011 Project Execution Standards

The design, manufacturing, and acceptance specifications of this system are mainly carried out in accordance with the following standards and technical specifications:

u GB3095-1996 "Atmospheric Environmental Quality Standard"

u GB13223-2003 "Emission Standards for Air Pollutants from Thermal Power Plants"

u GB18485-2007 "Control Standards for Pollutants from Domestic Waste Incineration"

u HJ/T75-2007 "Technical Specifications for Continuous Monitoring of Flue Gas Emissions from Thermal Power Plants"

u CJJ90-2002 "Technical Specifications for Municipal Domestic Waste Incineration Engineering"

u CJ/T118—2002 "Technical Specifications for Municipal Solid Waste Incinerators"

u HJ/T76-2007 "Technical Requirements and Detection Methods for Continuous Monitoring Systems for Flue Gas Emissions from Stationary Pollution Sources"

u GB16297-1996 "Comprehensive Emission Standard of Air Pollutants"

u GB/T16157-1996 "Methods for determination of particulate matter in exhaust from solid pollution sources and sampling of gaseous pollutants"

u GB9078-1996 "Comprehensive Emission Standard of Air Pollutants for Industrial Kilns"

u GB 3095-1996 "Ambient Air Quality Standards"

u GB12519-1990 "General Technical Conditions for Analytical Instruments"

000012 Project Plan

000012.1 Measurement items

Ø SO2, NOX, O2, smoke, temperature, pressure, flow rate

000012.2 Measurement method

Ø Flue gas sampling method: extraction condensation method

Ø SO2, NOX monitoring method: differential optical absorption spectrometry (phosphoric acid titration pretreatment)

Ø O2 monitoring method: electrochemical method

Ø Smoke and dust measurement method: extraction measurement method

Ø Temperature measurement method: temperature sensor

Ø Pressure measurement method: pressure sensor

Ø Flow velocity measurement method: Differential pressure method (Pitot tube)

2. System General Principles

The technical requirements in functional design, structure, performance, installation and testing of this system equipment all comply with the relevant national environmental protection standards and meet the environmental protection industry standards of the People's Republic of China (HJ/T75-2007, HJ/T76-2007) Require.

The company's CEMS system consists of a gaseous pollutant monitoring subsystem, a particulate matter monitoring subsystem, a flue gas parameter monitoring subsystem and a data acquisition and processing subsystem. The gaseous pollutant monitoring subsystem and data acquisition and processing subsystem are installed in the standard Inside a 19-inch cabinet. The system composition is as follows:

Figure 1. CEMS system composition diagram

Ø Gaseous pollutant monitoring subsystem: composed of sampling unit, pretreatment unit and analysis unit.

Ø Particulate matter monitoring subsystem: using an extractable smoke and dust monitor.

Ø Flue gas parameter monitoring subsystem: Pitot tube is used to measure flow rate, pressure sensor is used to measure pressure, temperature sensor is used to measure temperature, and flue gas humidity is measured using high-temperature capacitive humidity sensor.

Ø Data acquisition and processing subsystem: composed of data collector, industrial computer, display and system software.

The above subsystems are tailored according to different customer needs.

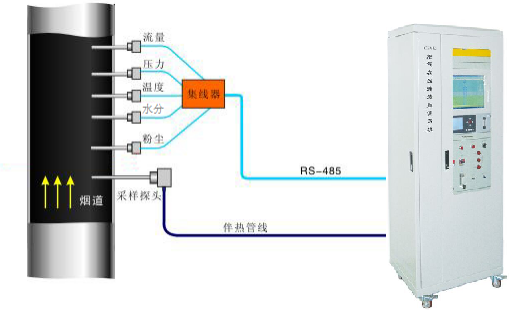

Figure 2. CEMS system installation diagram

3. System composition

3.1 Monitoring of gaseous pollutants

3.1.1 Sampling and preprocessing unit

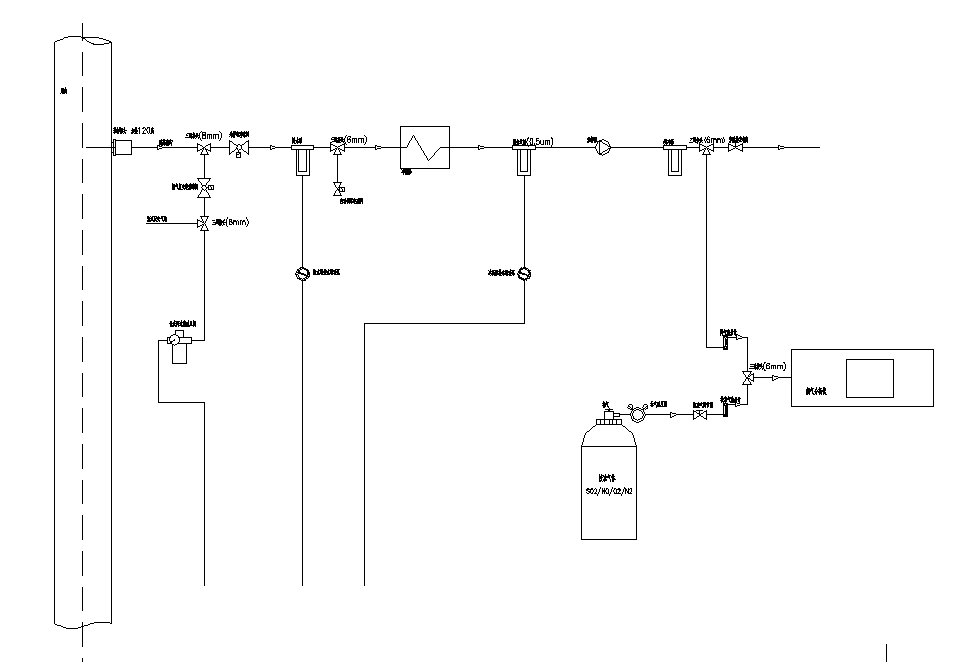

The sample gas is taken out by the sampling probe under the force of the sampling pump. Most of the particulate matter in the sample gas is filtered out by the filter in the sampling probe. After filtering, it is transported to the refrigeration system by the heating pipeline to condense and remove water, and then sent to the analysis unit for analysis. Among them, according to the common characteristics of high humidity and low SO2 in ultra-low systems, in order to reduce the adsorption loss of SO2, the pretreatment system adopts a relatively reliable and simple phosphoric acid titration method, adding more than 5% phosphoric acid solution in the condenser pretreatment, so that The condensed water is always in an acidic state, reducing SO2 adsorption loss and improving measurement accuracy. The condensed water is drained away through the drainage system. The control unit implements functions such as backflush, calibration, and refrigeration temperature alarm prompts, and displays various working states of the system.

The pretreatment system uses one-stage rapid condensation to remove water to ensure that the gas composition remains unchanged. Two-stage fine filtration is used to ensure that the gas measurement chamber is not contaminated, thus extending the service life of the analyzer. The figure below is the flow chart of the gaseous pollutant monitoring system.

3.1.2 Gas analyzer

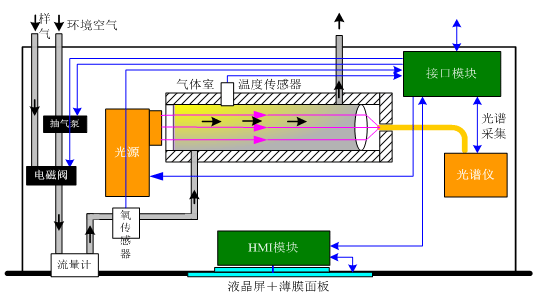

Instrument: UV Spectroscopic Gas Analyzer

Model: HM-UVA-100

Measurement principle: Differential optical absorption spectroscopy (DOAS)

Measurement principle

The UV spectrum gas analyzer is a gas analysis instrument based on multi-channel spectral analysis technology (OMA) and differential optical absorption spectrometry (DOAS). The light beam emitted by the light source converges into the optical fiber and is transmitted to the gas chamber through the optical fiber. After passing through the gas chamber, it is absorbed by the gas to be measured and then transmitted to the spectrometer by the optical fiber. It is split by the grating inside the spectrometer, and the array sensor converts the split optical signal. As an electrical signal, the continuous absorption spectrum information of the gas is obtained. The instrument uses differential absorption spectrum algorithm (DOAS) and partial least squares algorithm (PLS) to process based on this spectral information to obtain the concentration of the measured gas.

Ø Multi-band spectral analysis technology (OMA)

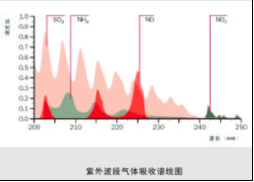

Since various gas molecules absorb light waves differently in different wavelength bands, simultaneous measurement of multiple gases can be achieved by analyzing the continuous spectrum after gas absorption.

The UV spectrum gas analyzer uses a light source and sensor in the ultraviolet band to measure the concentration of gases that absorb light waves in the ultraviolet band, such as SO2, NO, NO2 and other gases.

Ø Differential optical absorption spectroscopy (DOAS)

The core idea of DOAS is to decompose the absorption spectrum of gas into two parts: fast changing and slowly changing parts. The fast-changing part is related to the structure and elements of the gas molecules, and is the characteristic part of the gas molecule absorption spectrum; the slowly-changing part is related to the interference of smoke, water vapor, background gas, and changes in the measurement system, and is the interference part. DOAS uses a fast-changing part to calculate the concentration of the gas being measured, and the measurement results are uninterrupted and have high accuracy.

The UV spectrum gas analyzer adopts a unique processing method that combines the DOAS algorithm and the PLS algorithm to eliminate the interference of smoke, water vapor, and background gases. It also eliminates the impact of measurement system fluctuations on the measurement results, ensuring the accuracy and accuracy of the measurement. stability.

Technical indicators

SO2: 0~20~100ppm (can be customized according to buyer’s needs)

NO: 0~20~100ppm (can be customized according to buyer’s needs)

Accuracy: ≤±2%

Linear error: ≤±2%FS

Zero point drift: ≤±2%FS/7D

Range drift: ≤±2%FS/7D

Response time: ≤30s

other

O2 measurement electrochemistry, 0~25%, ≤±2%FS

Power supply: 220VAC, 50Hz

Ambient temperature limit: -10~40℃

Communication interface: 1 channel RS232; 1 channel RS485/RS232

Digital interface: 4 relay outputs, 2 binary inputs

Analog interface: 5 channels 4~20mA output, 2 channels 4~20mA input

Instrument features

Ø High reliability

It uses a pulse xenon lamp with a lifespan of 10 years as the light source and a curing spectrometer. It has no moving parts and is highly reliable.

Ø Combined gas chamber design

The combined gas chamber design makes spectral adjustment easy and improves spectral intensity.

Ø High measurement accuracy and good stability

Using the DOAS (Differential Optical Absorption Spectroscopy) algorithm, the measurement results are not interfered by smoke, moisture and other factors, and the measurement accuracy is high; at the same time, the DOAS algorithm also eliminates errors caused by instrument aging, and the measurement stability is good.

Ø Highly intelligent and digital

It has multiple built-in high-performance processors, and high-speed data bus communication technology is used between the processors. Each module has powerful digital configuration and detection functions; it is simple to operate and easy to use.

Ø Rich user interface

Provides rich interfaces and can be easily integrated into various control and monitoring systems. Wireless or wired networks can be established through communication methods such as RS485 and RS232 to facilitate the daily operation, maintenance and management of the instrument.