Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

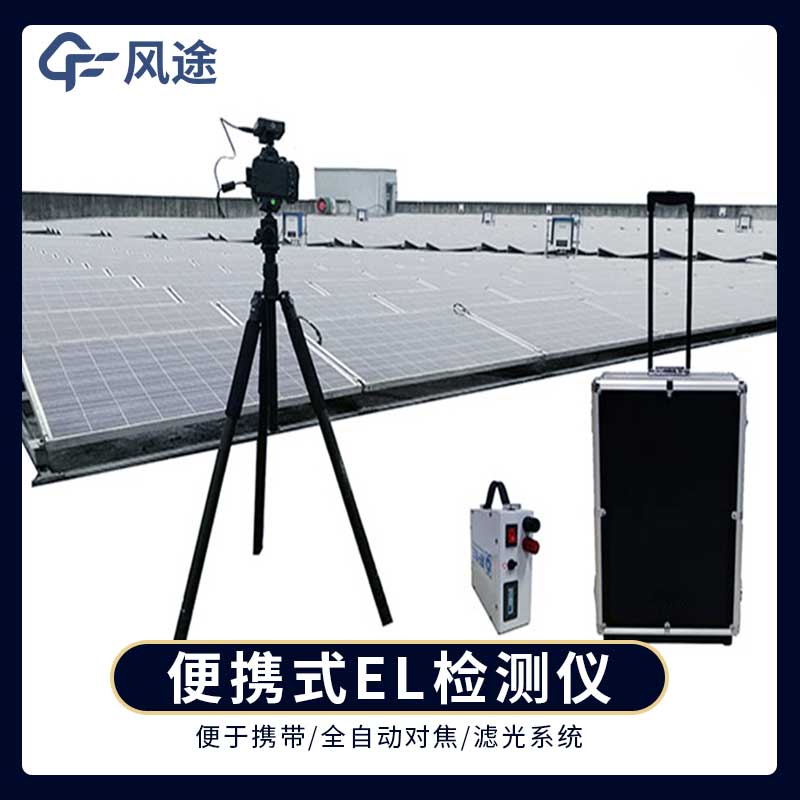

el defect detector product introduction:

The EL defect detector is also called the solar cell module EL defect detector. The EL defect detector is an internal defect detection equipment for solar cells or battery components. It uses infrared testing to test the cell components to achieve EL imaging mode, so that it can Check if there are any internal defects in the cell assembly. The el defect detector is used to detect internal defects in photovoltaic solar panels, which can better help users complete product quality inspection and control production and installation risks.

The el defect detector is equipped with a 24 million-level infrared camera that can effectively help users discover DC quality problems inside photovoltaic panels. The equipment is equipped with energy storage power supply and Wi-Fi wireless control module, making on-site inspection more convenient and faster.

el defect detector application scenarios:

It is suitable for photovoltaic power station component arrival inspection and post-installation component testing on the bracket, as well as component quality testing in warehouses/laboratories/factories.

el defect detector can identify defect types:

Hidden crack | scrap | fragments | broken gate | black heart | Virtual soldering |

process contamination | low efficiency slice | Black border | sintering | Excessive | perforation |

el defect detector product features and advantages:

1. 24 million level high-definition infrared camera, EL image quality is clearer

2. The full-time autofocus module has higher imaging accuracy

3. Wireless control equipment detection and rapid imaging

4. On-site inspection of program-controlled constant current power supply enables 24-hour uninterrupted testing

5. Tablet PC wireless detection image transmission and viewing without a camera to view the detection image

6. On-site inspection of energy storage power supply can be tested without any preparation.

7. Multi-angle testing of components on the 2-meter carbon fiber tripod bracket is more convenient

8. Wireless remote operation test of the whole machine, one person can complete the entire project

9. The three-proof trolley case is light and safe to carry and transport.

EL defect detector application fields:

Scenes | Factory components, warehouse components, power station on-site component testing, |

test | Daytime: outdoor anti-infrared darkroom test; indoor no-sunlight environment test Night: Direct tripod test, light and moonlight have no effect |

object | Crystalline silicon components, thin film components (can be customized) |

quantity | Single module imaging inspection |

el defect detector specifications:

module | Configuration | Specification |

camera module | Pixel | 24.16 million pixels |

resolution | 6000x4000 | |

chip | 23.5x15.6mm, CMOS sensor | |

Infrared chip | Lailx9s germanium chip 99.8% infrared refractive index | |

Accuracy | 1.0mm/pixel | |

Detection speed | Adjustable from 1 to 30 seconds | |

Weak current test | Can present clear crack imaging at 5A weak current | |

light shielding | Light, moonlight, starlight, slight indoor sunlight, and sunlight below 100 irradiance have no effect on the test | |

Detection area | 4000mm*2000mm | |

lens | 18mm wide angle infrared lens | |

focus mode | Full-time autofocus | |

Battery | 980mah | |

Memory card | 32GB | |

data cable | 10cm | |

Power module | capacity | 10AH |

Batteries | High performance lithium battery | |

Output current | 8A | |

Current accuracy | 0.1A | |

The output voltage | 70V | |

Voltage accuracy | 0.1V | |

Load power | 100W~600W; the upper limit is not higher than 700W | |

Test quantity | 300 to 500 photovoltaic panels | |

control Panel | LED digital display program control panel | |

Function settings | Wireless remote control power on and off | |

Power saving mode | Automatically power off after 10 seconds of power on | |

Steady state module | Constant power supply output current and voltage are not affected by changes in battery capacity | |

circuit protection | Short circuit protection, open circuit protection, current backflow protection, overheating protection, electrostatic protection, current and voltage adaptive matching photovoltaic panels | |

On the wire | 10cm AC three-hole input cable | |

DC line | 5m DC output cable, MC4 port docking component | |

computer | tablet | Huawei Tablet 32G |

Wi-Fi | 2.4G | Built-in 2.4G Wi-Fi wireless control module |

software | Detection APP | Wirelessly control camera detection and photography, image transmission and imaging, dynamic video framing and positioning, historical picture viewing, image downloading, etc. |

PC | Computer Software | Automatic detection, defect classification identification and storage, folder date pipeline, statistics, gain, screenshots, camera parameter adjustment, professional management desktop software |

bracket system | Detection bracket | 1.5m aluminum alloy bracket |

Detection PTZ | Integrated bracket installation, 360-degree rotation | |

Positioning module | Detect positioning | The cross laser positioner can quickly locate the position of the rear components on the bracket, which can improve the detection efficiency several times. |

Usage environment | Deserts, plateaus, rooftops, hills, slopes, factories, rooftops, snowfields, greenhouses, agriculture-solar complementation, fish-light complementation, scenery-solar complementation, and other environments | |

Warranty and after-sales service | 2-year warranty, 24H response, 72H fault solution, spare parts coordination | |

el defect detector configuration list:

serial number | name | Specification | quantity | unit |

1 | EL camera | 24 million infrared camera, fully automatic focus | 1 | tower |

2 | EL infrared lens | 18mm wide-angle infrared lens; accuracy 0.8mm | 1 | tower |

3 | tablet | Huawei Honor 32G | 1 | tower |

4 | Wi-Fi transmission module | Built-in 2.4G Wi-Fi module | 1 | set |

5 | Data cable/charger | standard | 1 | set |

6 | camera battery | standard | 2 | set |

7 | Detection bracket | 2m carbon fiber tripod | 1 | set |

9 | Detection PTZ | 720 PTZ | 1 | tower |

10 | EL-DC mobile power supply | 10AH energy storage, 70V, 700W, constant current and constant voltage output, wireless remote control, battery life of 300~500 components, automatic power off in 10S | 1 | tower |

11 | On the wire | 5 meters | 1 | root |

12 | Detection locator | Cross laser positioning, rapid positioning and detection of component position | 1 | set |

13 | Equipment trolley case | Special three-proof instrument trolley case; | 1 | set |

14 | EL-APP detection software | Wireless operation camera detection, real-time view, image transmission viewing, image download, historical image viewing | 1 | set |

15 | windows software | Automatic detection, defect classification identification and storage, folder date pipeline, statistics, gain, screenshots, camera parameter adjustment, professional management desktop software | 1 | set |

* | Applicable scene | Pre-installation testing of photovoltaic power stations; component testing on brackets | ||

* | other | Standard application equipment, mainstream products in the market. |