Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

1.Application environment description of Suspended Solids Sensor

Suspended Solids Sensor is a device for measuring the concentration of suspended matter in solution (sludge turbidity), using an optical measurement method without chemical reagents.The concentration of suspended solids in water is measured by using the scattering or absorption characteristics of light. It has high sensitivity, fast response and real-time monitoring capabilities, and is widely used in water quality monitoring and sewage treatment.

Signal output: RS485 (MODBUS-RTU). Infrared LED light source, strong anti-interference ability.

Internal signal isolation technology, strong anti-interference.

Good reproducibility, thermal stability, low drift, small size, fast response

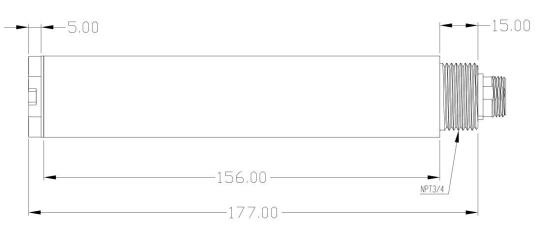

Easy and simple installation, 3/4NPT pipe thread, convenient for submerged installation or installation in pipes and tanks, stable performance and long service life

IP68 waterproof standard

2. Suspended Solids Sensor Technical Performance and Specifications

1.Suspended Solids Sensor Technical Parameters

| Measuring principle | Scattered light method |

| Signal method | RS485 (MODBUS-RTU) |

| Measuring range | 0~2000mg/L |

| Measurement resolution | 0.1mg/L |

| measurement accuracy | ±5% (depending on sludge homogeneity) |

| shell material | Glass and ABS |

| cable length | Standard 5 meters |

| Supply voltage | 12-24VDC (0.4W@12V) |

| Calibration method | Two-point calibration |

| Measurement environment | Temperature 0~50℃ (no freezing), < 0.2MPa |

| waterproof level | IP68 |

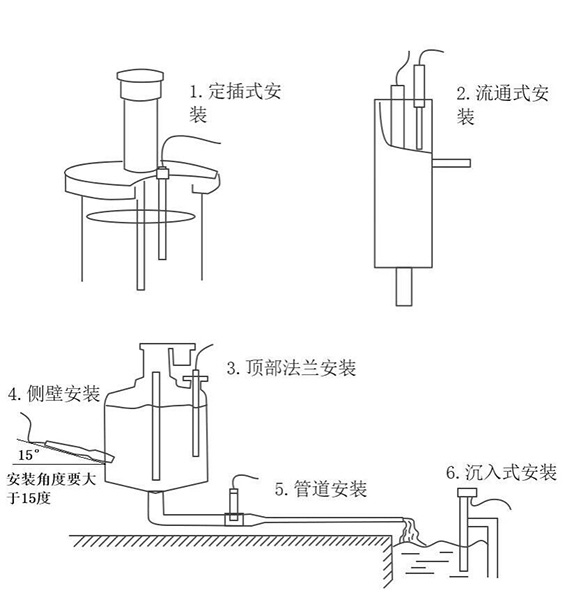

| Installation | Immersion installation, NPT3/4 thread |

2.Suspended Solids Sensor Dimensions

The sensor connector is an M12 aviation plug connector with 5 pins.

3. Suspended Solids Sensor Installation and Electrical Connection

1.Suspended Solids Sensor Installation

Note: The sensor cannot be installed upside down or horizontally, but must be installed at an angle of at least 15 degrees.

2. Suspended Solids Sensor Electrical Installation

The cable is a 5-core shielded cable, and the line sequence definition is:

Brown-power line (12~24VDC) Black-ground line (GND)

Green-485B Yellow-485A

The wiring sequence should be carefully checked before powering on to avoid unnecessary losses due to wiring errors.

4. Suspended Solids Sensor Maintenance and Care

1. Use and maintenance

The sensor's measurement window is one of the key components to ensure the sensor works properly and measures accurately. Its cleaning requirements are critical to ensure the accuracy and reliability of the measurement.

1.1 Maintenance methods

1. Regular cleaning: The measuring window should be cleaned regularly to remove dirt, sediment and other impurities attached to the surface. The cleaning frequency depends on the measurement environment, but it is generally recommended to clean it every day or every week.

2. Use mild detergent: When cleaning, you should choose a mild detergent and avoid using detergents containing abrasives or acid-base components to prevent damage to the surface of the measuring window.

3. Soft cloth or sponge: During cleaning, use a soft cloth or sponge to gently wipe the surface of the measuring window to prevent scratches or abrasions.

4. Avoid direct contact: Avoid touching the measuring window surface directly with your hands during cleaning to reduce contamination from fingerprints and grease.

5. Rinse: After cleaning, the measuring window should be rinsed thoroughly with clean water to ensure that residual detergent and dirt are removed.

6. Drying: After cleaning, use a dry soft cloth to gently wipe the surface of the measuring window to remove water stains and ensure complete drying.

7. Regular inspection: Regularly check whether the measuring window surface is damaged or worn to maintain the normal operation of the sensor.

8. Avoid exposure to chemicals and high temperatures: Avoid exposing the measurement window to harmful chemicals or high temperatures to prevent damage or corrosion to its surface.

When the sensor has been used for a long time and measurement errors occur, it can be calibrated and corrected by using the instrument. If the sensor cannot be calibrated and measured after the above maintenance and care, it means that the sensor has failed. Please replace the sensor.

5. Notes on Suspended Solids Sensor

1. The measuring window contains glass components, so avoid scratching the surface with sharp or hard objects to prevent scratches and damage.

2. The sensor contains sensitive optical components and precision electronic devices. Avoid exposing it to severe vibration or impact to prevent displacement or damage to the optical parts and electronic devices. No maintenance is required inside the device.

3. When not in use, appropriate dust covers or sleeves should be used to protect the optical parts from dust and contaminants.