Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

Technical indicators: TSP, PM2.5, and PM10 are all the same.Each unit can only measure one parameter.

Dust Monitoring System can continuously monitor and display the mass concentration of dust particles in the air environment in real time 24 hours.

1.Introduction to Dust Monitoring System

Dust Monitoring System (β-ray) uses the β-ray method to monitor the concentration of atmospheric particulate matter.The implementation standards of this product are as follows:

HJ/T 374—2007 Technical requirements and detection methods for total suspended particulate matter samplers

HJ/T 93-2013 Technical requirements and detection methods for environmental particulate matter (and) samplers

HJ 1100-2020 Technical Guidelines for Automatic Monitoring of Particulate Matter (and) Beta Ray Method in Ambient Air

2.Working principle of Dust Monitoring System

The working principle of the beta ray absorption method is adopted.C-14 is used as the emission source, which emits constant high-energy electrons.The sample air passes through the cutter and passes through the sampling tube at a constant flow rate, and the particles are trapped on the filter membrane.When beta rays pass through the filter membrane, the energy is attenuated.The mass of the particulate matter is calculated by measuring the attenuation.The concentration of particulate matter in the ambient air under actual conditions is calculated based on the sampling flow rate, sampling time and filter membrane area.This equipment is suitable for online monitoring of particulate matter at construction sites, road construction, factory boundaries, etc.

3.Dust Monitoring System functions and features

1) Use intelligent heating technology to dynamically heat and dehumidify the sampled air to improve measurement accuracy.

2) Using PID constant flow algorithm, the pump speed control is adaptive to ensure stable and accurate sampling air flow.

3) Use the five-level calibration method to ensure that PM10 concentration can be accurately measured regardless of high or low.

4) Use full zero-point calibration to ensure that every measurement is not affected by the uniformity of the filter paper.

5) The sampling period is continuously adjustable, with a minimum period of 3 minutes and a maximum period of 60 minutes.

6) Support paper-saving mode, the filter paper can be recycled according to usage, which can effectively extend the use time of the filter paper.

7) Supports local data query and display, and can query data in any time period.

8) Support wired network communication and 4G wireless communication

9) Support remote system upgrade and parameter setting

10) Supports local data storage, and the data storage period can be up to 365 days.

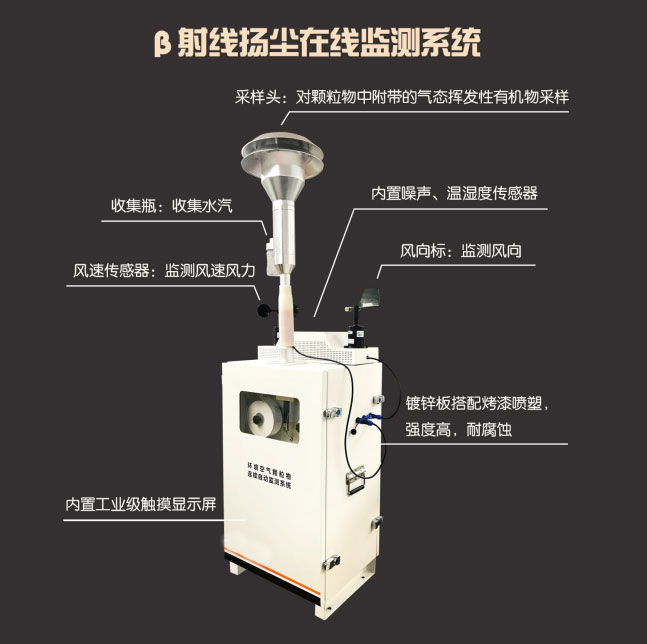

4.Dust Monitoring System product appearance

5.Dust Monitoring System technical specifications

1) Mechanical particle cutter to achieve precise cutting of particle size.

2) Use intelligent heating technology to dynamically heat and dehumidify the sampled air to improve measurement accuracy.

3) Using PID constant flow algorithm, the pump speed control is adaptive to ensure stable and accurate sampling air flow.

4) Use the five-level calibration method to ensure that PM10 concentration can be measured accurately regardless of high or low levels.

5) Use full zero-point calibration to ensure that every measurement is not affected by the uniformity of the filter paper.

6) The sampling period is continuously adjustable, with a minimum period of 3 minutes and a maximum period of 60 minutes.

7) Supports local data query and display, and can query data in any time period.

8) Support wired network communication and 4G wireless communication

9) Support remote system upgrade and parameter setting

10) Supports local data storage, and the data storage period can be up to 365 days.

11) 7-inch LCD display, direct on-site setting operation and system setting.

12) It has a fog cannon linkage function, which can control the opening and closing of fog cannon and other management equipment by setting the linkage threshold.

13) It can store 12 months of minute data and copy it through a USB flash drive.

14) Equipped with sampling pipeline and relative humidity calibration functions to effectively suppress the impact of humidity on measurement results.

| Measuring range | 0~10000μg/m³ | Input power | AC220V,50HZ |

| Measurement resolution | 1μg/m³ | power | <350W(MAX) |

| Measurement accuracy | 15.6% | noise | <65dB |

| air flow | 16.7L/m³ | working environment | -20~65℃ |

| Product size: (length*width*height mm) | 432*346*1400 | quality | 39KG |

Dust Monitoring System system composition

The system is mainly composed of particulate matter and meteorological monitoring units, data collection and processing units, video character overlay units, data transmission units, data display platforms, linkage control units, etc., to realize construction site environmental monitoring, data upload, data display, statistical analysis, and video overlay and other functions, perfectly connected with the government monitoring platform to realize 24-hour supervision of the construction site environment.

1.Particulate matter monitoring unit

Continuous and automatic monitoring of PM10, environmental data is collected every hour, and uploaded to the data center and monitoring platform for statistics in real time

and analysis;

2.Meteorological five parameter monitoring unit

The entire set of equipment is capable of monitoring environmental parameters such as temperature, humidity, wind speed, wind direction, and atmospheric pressure, and provides meteorological parameters for later analysis of monitoring data;

3.Data acquisition and processing unit

This unit is the center of the entire system.It identifies, checks and stores the collected monitoring data; it analyzes the collected monitoring data according to statistics.

It requires statistical analysis and processing, reporting the processed data to the cloud platform, and controlling the localized display of parameters to achieve the integration of environmental parameters and video surveillance images;

4.Data display platform

The monitoring data of this system can not only be reported to the data cloud platforms of governments at all levels, but also can be reported to the Fengtu Instruments beta ray online monitoring platform.It can also be integrated with the on-site surveillance video to display the on-site environmental parameters in the form of characters on the video surveillance On the screen, the integration of local environment parameters and local video is realized, which is stored together with the video to prevent tampering and will exist permanently once superimposed.

Main components of Dust Monitoring System equipment:

1.Equipment main box: dustproof, windproof, rainproof, and sunproof;

2.Particulate matter sampling head: physical cutter + heating dehumidifier + water vapor condenser

3.Industrial main control board + 7-inch touch screen: equipment system operation and operation

4.Particulate matter sensor: light scattering PM10 sensor

5.Temperature and humidity sensor: detects ambient temperature and humidity

6.Wind speed and direction sensor: meteorological data monitoring

7.Data transmission module: wireless collection and transmission module

8.Integrated circuit board: highly integrated, unified output

9.Power supply system: power supply, circuit breaker, ground wire

10.Bracket: 1.6m outdoor fixed rectangular bracket

11.Outdoor P10 LED display, 96×48 dot matrix (can be customized as required).

Meteorological monitoring unit

The entire set of equipment is capable of monitoring environmental parameters such as atmospheric pressure, temperature, humidity, etc.The later analysis of the data provides meteorological parameter protection.

temperature:

Measuring range: -45~80℃;

Resolution: 0.1℃;

Accuracy: ±0.5℃;

humidity:

Measuring range: 0~100%; Accuracy: ±3%;

Resolution: 1%;

Wind speed: Measuring principle: mechanical

Measuring range: 0~30m/s Starting wind force: ≥0.8m/s

Accuracy: ±(0.3+0.03V) (V: wind speed)

wind direction:

Measuring principle: mechanical measuring range: 8 directions

Starting wind force: ≥0.8m/s Accuracy: ±3 degrees Response and stability: ≤1min

Air pressure:

Measuring principle: Semiconductor

Measuring range: 300-1200hPa

Resolution: 0.1hpa

Accuracy: ±0.3hpa

Response and stability: ≤1min

Main technical features of the equipment

1.Have passed CPA, CCEP certification and have certification certificate.

2.Works normally within the environmental range of -30~60℃, 0~90%RH (no condensation)

3.According to customized requirements, the equipment can expand other monitoring interfaces on the box.

4.Mechanical particle cutter to achieve precise cutting of particle size

5.PID constant current algorithm ensures constant sampling flow and correct cutting curve

6.It has sampling pipeline and relative humidity calibration functions to effectively suppress the impact of humidity on measurement results; a unique built-in optimization algorithm improves the accuracy of instrument measurement results.

7.7-inch LCD screen, direct on-site setting operation, system setting

8.Supports remote upgrade of product firmware and modification of product configuration, eliminating the need for on-site operations, saving time and effort

9.Supports 4G/network port/WIFI communication methods to ensure real-time data transmission

10.Equipped with all-weather outdoor sensors to continuously monitor noise and meteorological parameter values

11.The default is to upload according to the HJ212 standard, and you can also customize the protocol to upload according to the requirements of the customer platform.

Dust Monitoring System product installation example