Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

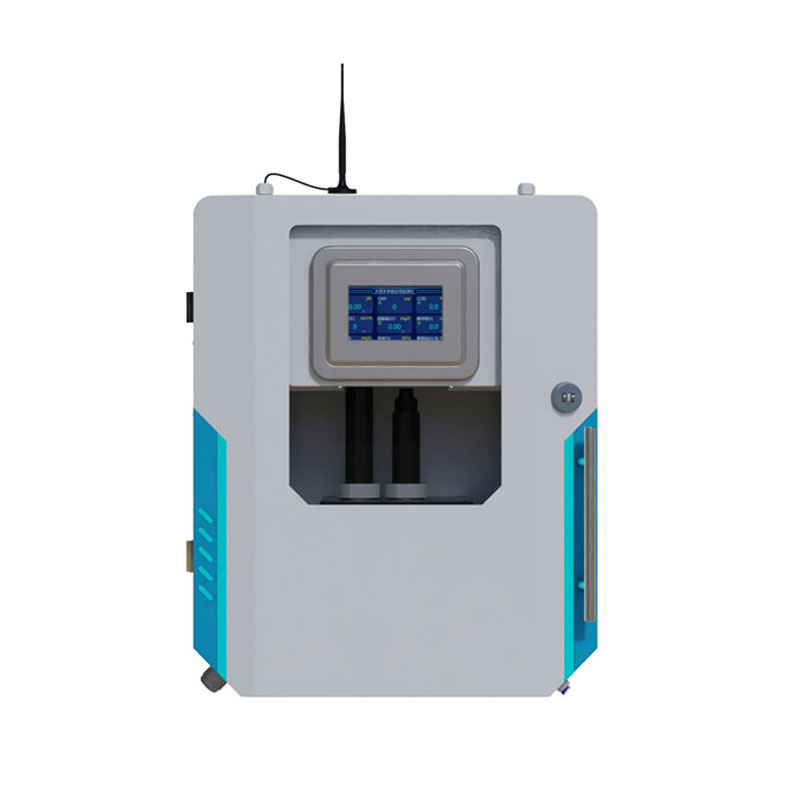

1、Distribution System Water Quality Monitor Product Introduction

Distribution System Water Quality Monitor applied to drinking water plants and water distribution plants, can monitor pH, dissolved oxygen, conductivity, turbidity, ORP, temperature.Distribution System Water Quality Monitor water quality monitoring system is a comprehensive sensor data collection, display, and historical curve monitoring system based on IoT technology.It consists of a flow stabilization and exhaust unit, an analysis and monitoring sensor unit, a system control unit, and a remote communication unit.It features comprehensive power supply, network communication, and real-time cloud-based data observation and analysis.

2、Distribution System Water Quality Monitor Applications

This device is designed for online water quality monitoring at water supply terminals with a pressure below 0.3 MPa.It can be widely used in urban and rural waterworks, water distribution networks, secondary water supply systems, user terminals, indoor swimming pools, large-scale water purification facilities, and direct drinking water.It is an essential online analyzer for water plant production process control, water conservancy, water management, and health supervision.

3、Distribution System Water Quality Monitor Functions and Features

1.4G GPRS networking.

2.Supports RJ45 network expansion.

3.Supports remote sensor transmission.

4.4.3-inch touchscreen display.

5.Supports 8GB of data storage and TF card data export.

6.Supports one RS485 Modbus-RTU slave.

7.Supports multiple RS485 Modbus-RTU sensor expansions.

8.Supports IoT data display, storage, and analysis platform.

9.The platform supports data forwarding through multiple protocols, including TCP short links and HTTP.

4、Distribution System Water Quality Monitor System Components

The water quality monitoring microsystem consists of a power supply unit, a sensor data monitoring unit, a display unit, a flow cell unit, a remote communication unit, and an integrated box main unit.

1.Power Supply Unit

Power Adapter: AC220 to DC12V/2A.

2.Analysis and Testing Unit

The analysis and testing unit is mainly composed of residual chlorine, pH, water temperature, turbidity, and conductivity sensors, which are fixed to the flow cell through threads or tight fitting fixtures.The main parameters of the sensors are as follows

| Serial number | Sensor type | Measurement range | Measurement principle | Measurement accuracy | Note |

| 1 | Residual chlorine | 0~5.00 mg/L | Electrode method | Reading ±5%; ±0.3℃ | Free chlorine pH integrated |

| 2 | pH | 0~14 (ph) | Electrochemistry (salt bridge) | ±0.1PH; ±0.1℃ | |

| 3 | Temperature | 0~85℃ | High-precision digital sensor | ±0.1℃ | |

| 4 | Turbidity | 0~1000NTU | Scattering light method | ±1% | |

| 5 | Electrical conductivity | 0~10000uS/cm | Contact method of electrode | ±1.5% |

3、Integrated enclosure main unit

| Installation method | Rack-mounted on the wall with a matching hanging bracket. |

| Dimensions | 520X240X210mm (excluding external communication antenna) with antenna total height 800mm |

| Case material | 304 Stainless Steel. |

| Protection level | IP54 |

| Power supply | AC220V Internal Power Adaptor AC220 to DC12V/3A |

| Inlet | PE pipe of 2-point water purifier with an outer diameter of φ6.5, flow rate of 500 mL/min, and pressure of 0.1-0.2 MPa. |

| Outlet | PE pipe of 2-point water purifier with outer diameter φ6.5, flow rate 400 mL/min |

| Discharge outlet | PE pipe of 2-point water purifier with outer diameter φ6.5, flow rate 100 mL/min (manual regular drainage can also be done) |

Note: The sensor should not be installed upside down or horizontally.It should be installed at a minimum angle of 15 degrees.

The operating environment of the above water quality sensors is 0-50°C and <0.3 MPa.

The sensor can be configured to meet specific monitoring requirements.The above sensor parameters are only for reference.Please read the sensor manual for details.