Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

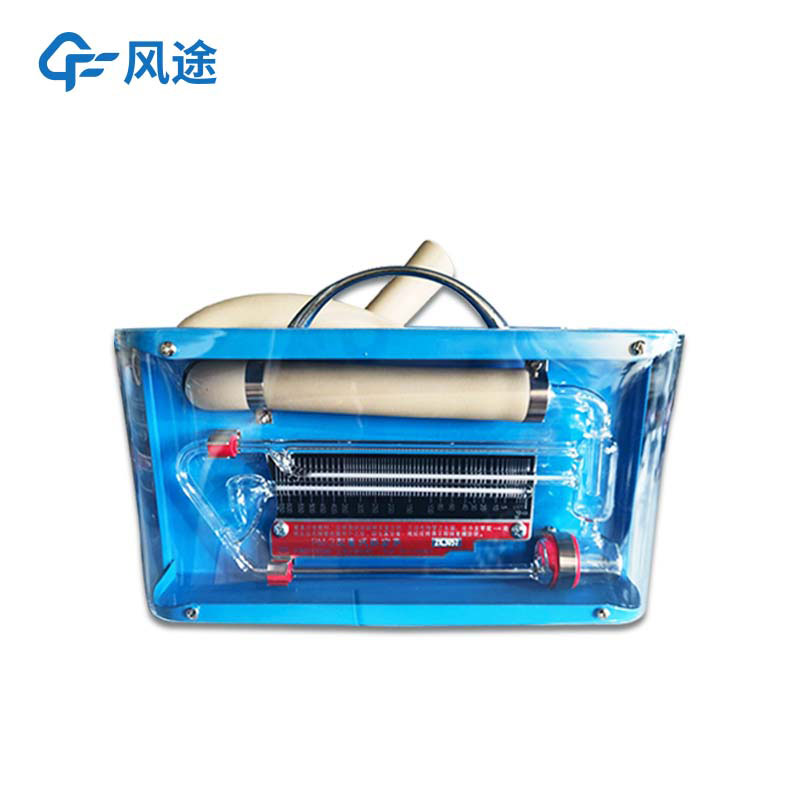

1.Product introduction of Maxi Vacuum Gauge

McLeod vacuum gauge, also known as McLeod vacuum gauge, fluid vacuum gauge, rotary compression vacuum gauge, McLeod vacuum gauge is a thermometer used for pressure measurement, based on ideal isothermal compression Boyle-Marriott The law measures the degree of vacuum, so the measured value has "absolute" meaning.

2. Purpose of Maxi vacuum gauge products

1. The McLeod vacuum gauge is mainly used to measure low vacuum in vacuum industrial production. It is widely used in central air-conditioning, refrigeration units, metallurgy, metal magnesium smelting, petrochemical industry, vacuum furnaces, vacuum drying ovens, electron tubes, and high-voltage power. Equipment, medicine, scientific experiments, educational research and metrology institutes, etc.

2. Because the Maxwell vacuum gauge can directly calculate the pressure value through its own parameters, in addition to measuring pressure, it can also be used as an "absolute vacuum gauge" to verify some relative vacuum gauges, such as resistance vacuum gauges, thermal vacuum gauges, etc. Couple vacuum gauge and thin film vacuum gauge, etc.

3. Technical parameters of Maxwell vacuum gauge

Specifications and models |

Measuring range |

Accuracy |

Implement standards or procedures |

Dimensions |

PM-2 |

0.1-650Pa-20KPa |

Soil 20% |

ZBY353-85Q/SSUPC01-2001 |

280x95x135mm (length x width x height) |

PM-3 |

0.1-650Pa |

Soil 20% |

||

PM-4 |

0.1-650Pa |

Soil 30% |

280x100x210mm (length x width x height) |

|

PM-3J |

0.1-1200Pa |

±8% |

||

PM-4J |

0.1-1200Pa |

Soil 10% |

4. Working environment conditions of Maxwell vacuum gauge

Temperature -5~38℃, relative humidity ≤85%

5. Installation and use instructions of McFarland vacuum gauge

1. Before installation: Take the Max vacuum gauge out of the package. First, carefully observe the glass tube part of the instrument. Under the premise of making sure that it is not broken, first cut off the nylon tie on the end of the vacuum hose near the instrument, and then remove the vacuum tube. Lift it upright to allow the working medium (Hg) in the tube to flow back into the glass tube.

2. Installation: Remove the nylon tie at the rubber plug end of the vacuum hose, take out the rubber plug, apply vacuum grease on the inner opening, and connect it to the vacuum equipment under test. The connection must be welded with a vacuum valve to control the opening and closing of the pipeline. If necessary, you can put a tight hoop on the interface and tighten the clamp to prevent air leakage.

3. Reading: Keep the instrument in a horizontal state (handle upward) and run the vacuum equipment for 1-3 minutes, then slowly open the vacuum valve and the instrument enters the measurement state, and lasts for 3-5 minutes in the measurement state (the size of the vacuum pump varies, and the duration varies. (length, judge based on experience during operation), hold the meter vertically to read, please refer to the printed instructions on the meter plate for specific operations.

4. End of measurement: The instrument should be returned to the horizontal state (handle upward) first, so that all the measurement medium returns to the lower end of the glass tube, and then the vacuum valve should be closed. If necessary, use a clamp to clamp the vacuum rubber tube to isolate it from the vacuum system. This can ensure that the mercury in the vacuum meter is clean, and can also prevent the vacuum meter from being shattered due to the strong impact of the atmosphere when the vacuum meter is removed and separated. After removing the vacuum gauge, be sure to close the valves of the mechanical pump and the vacuum system after the mechanical vacuum pump stops, and put the mechanical pump into the atmosphere to prevent mechanical oil from returning to the vacuum system and the vacuum gauge from being contaminated by oil.

6. Maintenance and maintenance of Maxwell vacuum gauge

1. When transporting or using the Maximeter, be careful not to lay it upside down to prevent the water-resistant silver from flowing back into the vacuum core tube or the mercury beads entering the middle closed-tube capillary and clogging the capillary, affecting the measurement accuracy. Therefore, the vacuum meter must be removed before each use. The tube is held vertically upward so that the mercury can flow back into the vacuum gauge glass tube.

2. The vacuum gauge should be in an upright state during measurement. It is strictly forbidden to put any gas into the direct air system strongly to avoid impacting the mercury in the glass tube and causing the glass tube to be broken.

3. During transportation or use of the Maxwell vacuum gauge, mercury beads may accidentally enter the middle glass capillary tube (closed measuring tube) and become stuck. At this time, a mechanical vacuum pump can be used to evacuate the Maxwell gauge separately and reciprocate the vacuum gauge. Rotating and swinging can make the mercury stuck in the glass tube flow back into the mercury container.

4. The working medium (Hg) of the vacuum meter, mercury, has been specially treated and has high purity. Mercury oxidation pollution caused by long-term use will directly affect the measurement accuracy. It should be returned to the factory for repair and calibration in time, and it can only be used after it is qualified.