Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

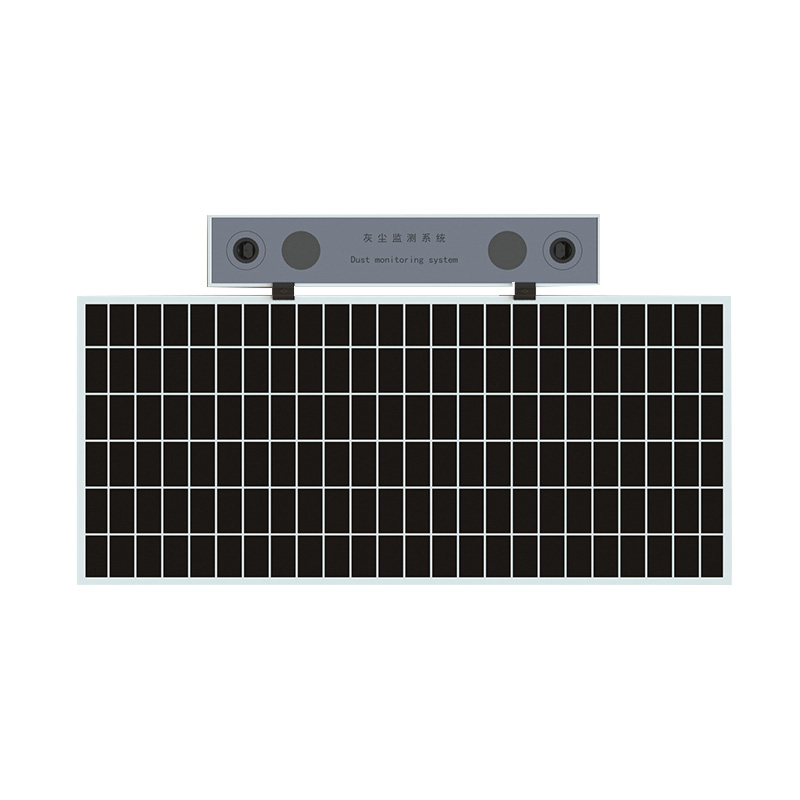

Photovoltaic module dust is a specialized device installed on the photovoltaic panel frame to monitor surface dust deposition in real time and quantify its impact on power generation. It measures light transmission loss caused by pollutants using optical principles, calculates the reduction in sunlight reaching the module, and supports remote monitoring and cleaning alerts to reduce energy consumption and improve power plant efficiency.

Photovoltaic module dust is a professional device directly installed on the photovoltaic panel frame. Its core function is to continuously and in real-time monitor dust deposition on the module surface and accurately quantify the specific impact of these pollutants on the power generation of the photovoltaic power plant. Dust accumulation on the surface of photovoltaic modules can lead to a decrease in power generation efficiency in various ways, such as blocking light, affecting heat dissipation, and even corroding the panel. The related losses are estimated to be at least 5% per year, and may be more significant in heavily polluted areas.

This instrument mainly uses advanced optical detection principles. For example, the commonly used blue light pollutant optical closed-loop measurement technology uses sensors to capture the scattering and reflection signals of light on dust particles. These optical parameters are converted into electrical signals and analyzed by a built-in processing unit, ultimately outputting an assessment of dust accumulation, such as the contamination ratio and cleanliness ratio. By continuously measuring the light transmission loss caused by contaminants on the glass, the system can calculate the actual reduction in sunlight reaching the solar cells, and then convert the contamination ratio into a real-time value for power generation loss. This allows maintenance personnel to accurately determine when contaminants reach the critical point requiring cleaning.

In terms of functionality, dust monitoring instruments form a key component of intelligent operation and maintenance. They can collect key data including contamination ratio, cleanliness ratio, and dust thickness. The instruments integrate an IoT communication module, supporting wired or wireless data transmission to a remote monitoring platform for real-time remote dust monitoring. When the surface cleanliness of the photovoltaic panels falls below a preset threshold, the system promptly alerts the user to clean, thus avoiding efficiency losses or cost waste caused by blind or delayed cleaning. Some systems can also automatically initiate cleaning operations using cleaning robots and other equipment based on set contamination thresholds.

Deploying such monitoring systems brings multiple practical benefits to photovoltaic power plants. First, by providing accurate cleaning decision-making basis, it transforms the operation and maintenance model from relying on fixed cycles or manual experience to scientific management based on actual contamination data, thereby optimizing cleaning costs. Secondly, timely cleaning effectively mitigates problems such as hot spot effects caused by dust accumulation, helping to extend the lifespan of photovoltaic modules. Finally, all monitoring data can be recorded and analyzed in depth over a long period, helping maintenance personnel understand the patterns and trends of dust accumulation in different areas of the power plant, providing data support for developing more efficient overall maintenance strategies. According to the recommendations of international standard IEC 61724-1, multi-point measurements within large photovoltaic parks can more comprehensively reflect the pollution status of the entire power plant, and the current economic viability of dust monitoring instruments makes this multi-point deployment scheme more feasible.