Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

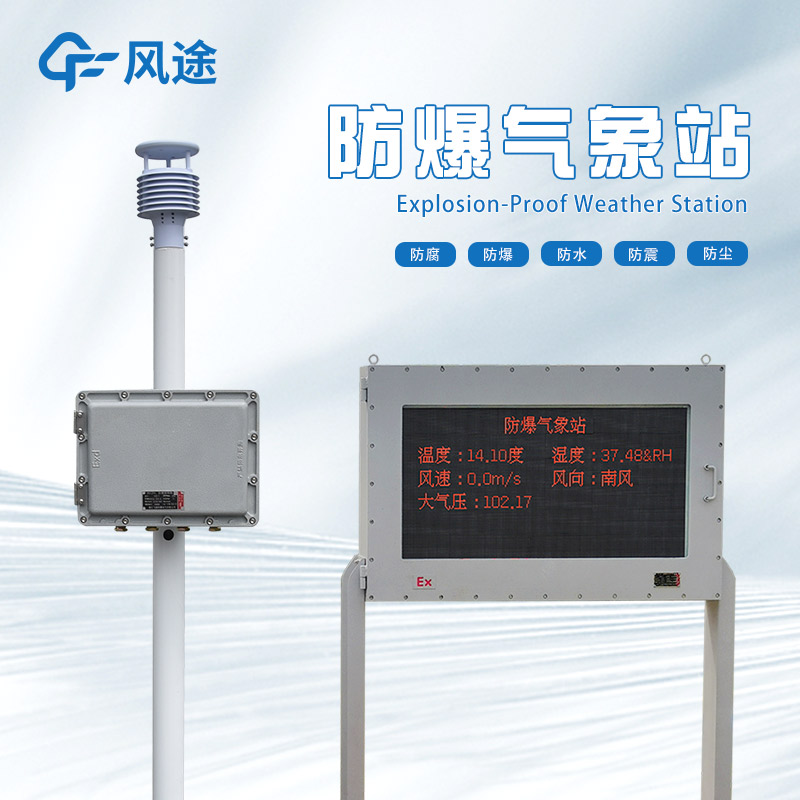

Due to its special production environment, chemical plants have a demand for explosion-proof weather stations.

This is because the chemical production environment is extremely special. On the one hand, a large amount of flammable and explosive gases and combustible dusts are generated, used and stored, such as hydrogen, methane, flour, coal powder, etc. When these substances are mixed with air in a certain proportion and encounter a fire source or electrostatic discharge, explosions are prone to occur. For example, the combustible gases released during the refining of crude oil in a refinery may explode when encountering static electricity. At the same time, meteorological conditions have a significant impact on their diffusion. Wind direction and wind speed determine the diffusion direction and speed of gases or dusts. When the wind speed is high, the leakage gas has a wider diffusion range, and the wind direction indicates the affected area downwind. On the other hand, chemical production is often carried out under high temperature, high pressure and complex chemical reaction conditions. For example, in the high-temperature reaction of the synthetic ammonia industry, high temperature enhances the activity of combustible substances, and high pressure increases the compression ratio of gases. Once the container ruptures and leaks, the gas expands instantaneously and may cause an explosion. Moreover, temperature changes in the weather will bring thermal stress to chemical equipment, affecting the performance and sealing effect of the equipment and increasing the risk of leakage.

Industrial Weather Station can monitor meteorological data such as wind speed, wind direction, temperature and humidity in real time. Based on this, the leakage and diffusion path and range of hazardous chemicals can be determined. For example, when the wind direction changes suddenly, timely warnings can be given so that the factory can take measures. Temperature and humidity data are of great significance for assessing the risk of fire and explosion. High temperature makes chemical substances volatile easily, and low humidity is prone to static electricity. When unfavorable meteorological conditions occur, early warnings can be given, and the factory can strengthen ventilation or stop high-risk operations. It can provide a basis for production scheduling. For example, when loading and unloading flammable and explosive chemicals, appropriate timing and operation methods can be selected by referring to meteorological data. For personnel, it can help workers make preparations for protection or evacuation in advance and ensure their life safety.

The installation of Industrial Weather Station is an important measure for chemical plants to meet safety regulations and environmental supervision requirements. It helps enterprises understand their own impact on the environment so that they can take effective environmental protection measures and promote sustainable development.