Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

Extreme weather has a significant impact. During the flood season, extreme weather such as high temperatures, high humidity, lightning, and heavy rain occurs frequently. High temperatures can cause the operation of process equipment in hazardous chemical enterprises to become unstable. The physical or chemical changes of certain chemicals may intensify under high temperatures, such as accelerated reaction speeds and increased container pressures, which are prone to causing explosions. High humidity poses a serious threat to chemicals that react with water, such as metals like potassium and sodium. They react violently with water, generating hydrogen gas and a large amount of heat, and are prone to explosion and combustion. If lightning strikes storage facilities or transportation vehicles, it may cause the combustion and explosion of hazardous chemicals due to electrostatic discharge. Heavy rain can trigger floods that may inundate warehouses or production facilities, leading to chemical leaks, environmental pollution, and endangering lives. These extreme weather conditions make hazardous chemical accidents more likely to occur.

By means of meteorological monitoring, enterprises can obtain forecast and early warning information. Based on the warnings, they can take preventive measures in advance. For example, when a heavy rain warning is issued, they can reinforce warehouses; when a lightning warning is issued, they can stop operations that are prone to generating static electricity and ground the equipment, etc., and increase inspections. Early warning, early preparation, and early prevention can ensure safety.

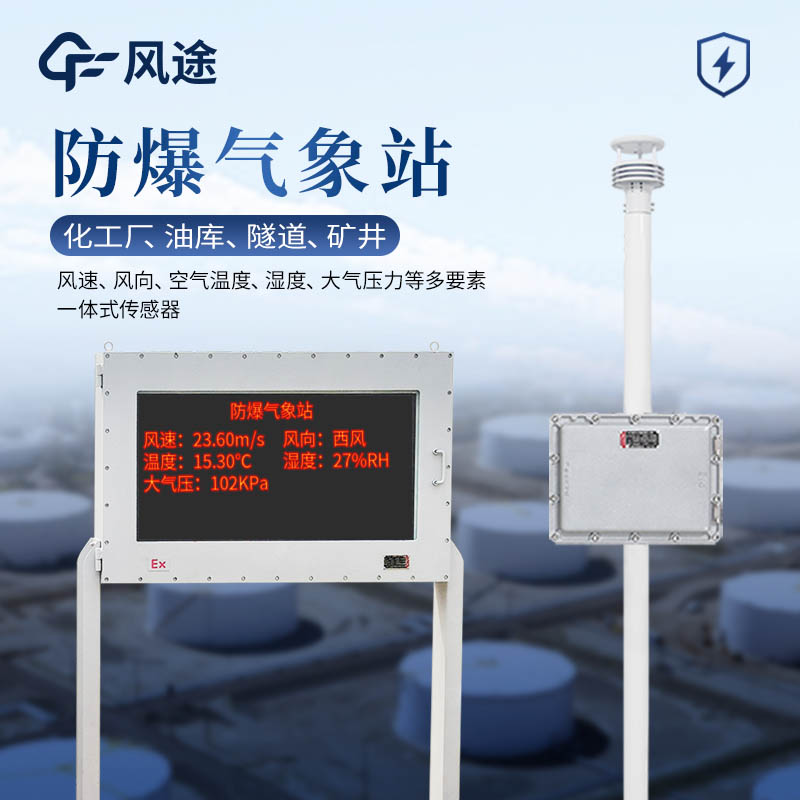

The Industrial Weather Station is designed for chemical enterprises. By integrating meteorological monitoring technology with rigorous explosion-proof design, it has built a solid defense line for meteorological information to ensure the safe operation of the chemical industry. This system can comprehensively monitor key meteorological elements such as temperature, humidity, wind speed, wind direction, and air pressure. These data are of crucial significance for the chemical production process and safety management.

The chemical weather station has three core functions: real-time monitoring, early warning prompts, and data storage and analysis. Real-time monitoring enables chemical enterprises to immediately grasp key meteorological information. The early warning prompt function can quickly issue alarms based on the monitoring data, guiding enterprises to take preventive measures to prevent accidents caused by meteorological factors. The data storage and analysis function allows enterprises to retain monitoring data for a long time, facilitating subsequent inquiries, analyses, and trend predictions.

In view of the special requirements of the chemical environment, the chemical weather station adopts a high-protection design, possessing properties such as anti-corrosion, explosion-proof, waterproof, shockproof, and dustproof to ensure stable operation in flammable and explosive environments. It supports multiple power supply methods such as solar power and mains power to adapt to different installation environments. The monitoring data can be transmitted to remote monitoring centers or explosion-proof display screens in wired or wireless forms, realizing efficient remote monitoring and management and improving the efficiency and safety of monitoring work.