Meteorological environment monitoring equipment supplier

Insist on doing high-precision customer favorite technology products

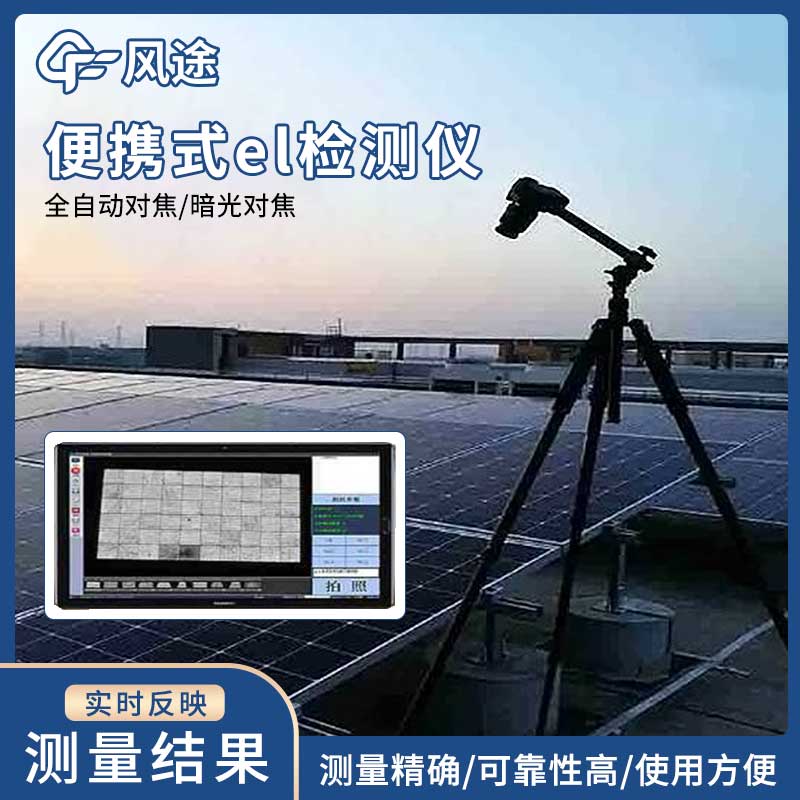

The El detector, also known as the electroluminescence (EL) tester, is a device that detects defects and monitors the production process of solar cell modules based on the electroluminescence characteristics of silicon materials. It uses infrared imaging technology to detect internal defects such as cell cracks, hidden cracks, black heart cells, broken grids, and poor soldering in the cell components, ensuring the quality of the components before they enter the next production stage.

The importance of the EL detector lies in its ability to detect anomalies within the silicon wafer by measuring changes in ion concentration at the PN junction, thereby ensuring the quality and efficiency of solar cell modules. The silicon wafer, as the base of the solar cell, directly affects the conversion efficiency and power generation efficiency of the cell. By using the EL detector, the circulation of substandard solar cells in the market can be reduced, and power losses in components can be minimized.

In production, common types of solar cell silicon wafers include monocrystalline and polycrystalline silicon. Due to the randomness of production conditions, these wafers may have defects such as edge impurities and dislocations, which can reduce the power generation efficiency and service life of the cells, and even affect the stability of photovoltaic systems. Therefore, it is crucial to classify the cells based on performance parameters, improve cell utilization, and produce qualified cell components.

The EL detector applies a current of 1-1.5 times the Isc to make the silicon wafer emit infrared light at 1000-1100nm, thereby detecting defects in the wafer. Common defects include black heart cells, black mass cells, short circuit black cells, broken grid cells, and hidden cracked cells. These defects can lead to partial damage or current loss in the cell, affecting the overall performance of the component.

In summary, the EL detector, through EL imaging technology, can quickly and accurately detect various defects in solar cells and components, such as hidden cracks, broken pieces, and black heart cells. It helps to improve the production process of solar cell components, control product quality, increase the yield, and avoid production waste.